In today’s highly interconnected digital age, the importance of interface technology as a bridge for communication between devices is self-evident.

From early serial and parallel ports to the globally widespread USB-A, and now the rapidly growing Type-C, each evolution of interfaces signifies a leap forward in technological application.

The Type-C interface, especially its core component—the Type-C female connector—has rapidly captured the market since its inception with its disruptive design, becoming the preferred choice for everything from flagship smartphones to thin and light laptops, and even various peripheral devices. However, like any technology, challenges exist beneath the surface.

This article aims to deeply analyze the advantages and disadvantages of the Type-C female connector and explore its underlying technological logic and future development trends.

I. The Revolutionary Advantages of the Type-C Female Connector

The advantages of Type-C are not accidental, but rather a comprehensive transcendence of traditional interfaces in its design philosophy. These advantages collectively constitute its strong market competitiveness.

1. Unparalleled Convenience: Reversible Insertion

This is Type-C’s most celebrated feature and the key to its rapid user acceptance. Traditional USB-A interfaces, due to their asymmetrical trapezoidal design, often require users to “try twice” to insert correctly.

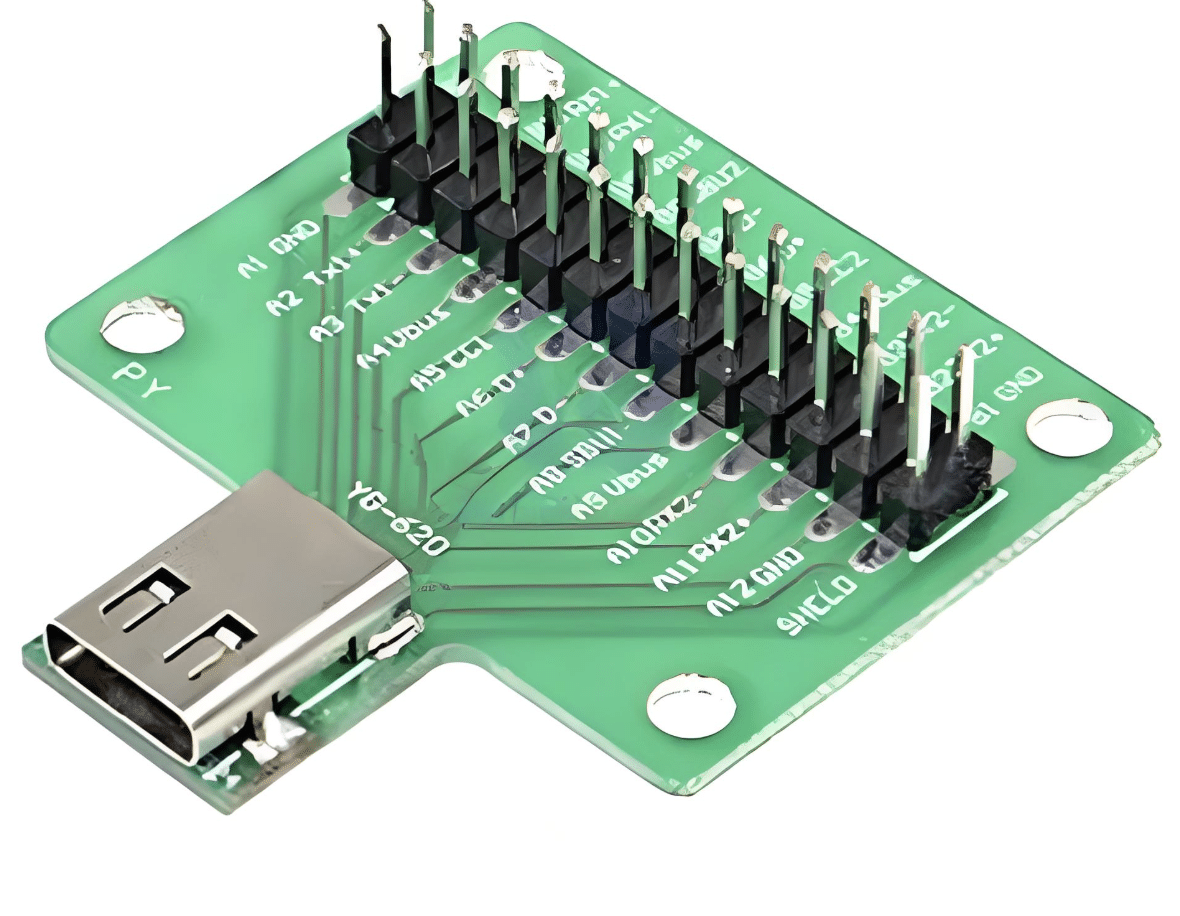

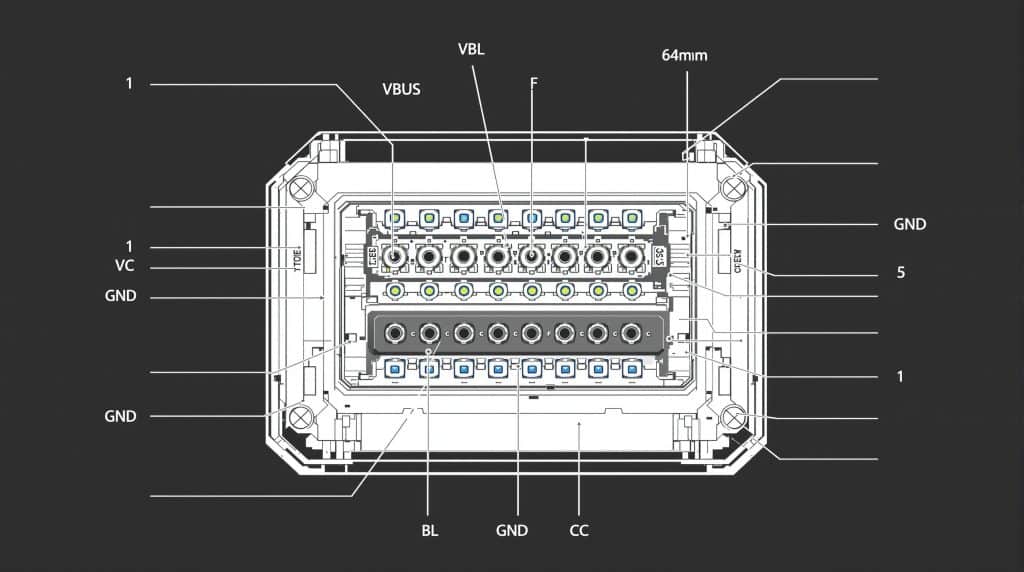

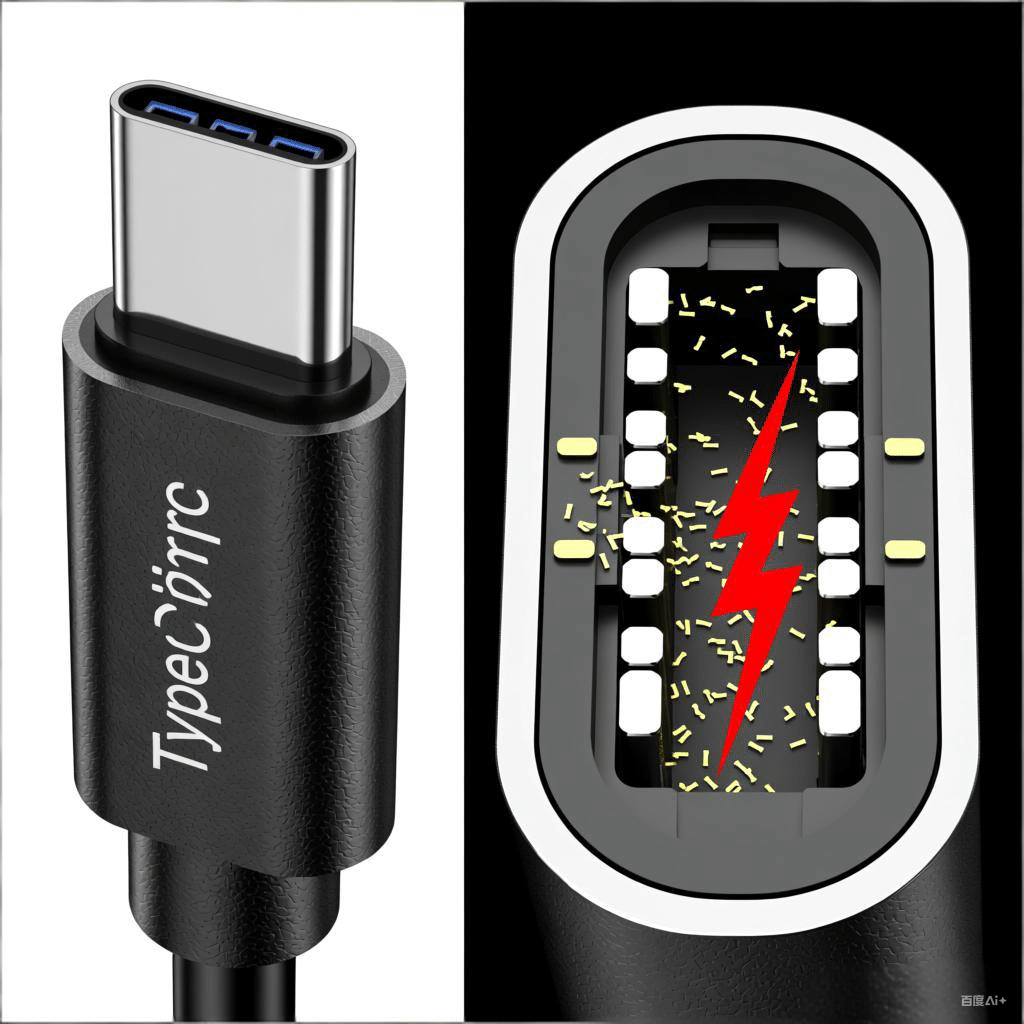

The Type-C female connector employs a perfectly symmetrical design, with all 24 pins arranged vertically. It automatically recognizes and establishes a connection regardless of the insertion direction. This is not merely physical convenience, but a philosophical revolution in user experience, eliminating the frustration of repeated attempts and truly achieving the freedom of “blind insertion.”

2. Robust Durability and High Standards

As mentioned in the link, the Type-C female connector can withstand up to 10,000 insertions and removals. Behind this figure lies stringent industrial standards and a deep understanding of materials science.

The metal casing and contact springs of the Type-C female connector are typically made of corrosion-resistant, high-strength phosphor bronze or beryllium copper, supplemented with gold or nickel plating to ensure stable electrical connection even under long-term physical friction.

This high durability is crucial for devices that require frequent plugging and unplugging (such as daily-charged mobile phones and laptops used as docking stations), directly improving product lifespan and reliability.

3. Extremely High Data Transfer Rates

Type-C is a physical interface form factor whose powerful data transfer capabilities depend on the supported protocol standards. A standard Type-C female connector can support USB 3.1 Gen 2 and even USB4 protocols. This means its theoretical data transfer speed can soar from 5Gbps (USB 3.1 Gen 1) to 10Gbps (USB 3.1 Gen 2), and even up to 40Gbps (USB4).

This high speed allows for the transfer of several gigabytes of high-definition video or large files in an instant, completely solving the bottleneck of traditional USB-A interfaces when transferring large amounts of data, providing a solid foundation for high-speed external storage (such as portable SSDs), high-resolution displays, and other devices.

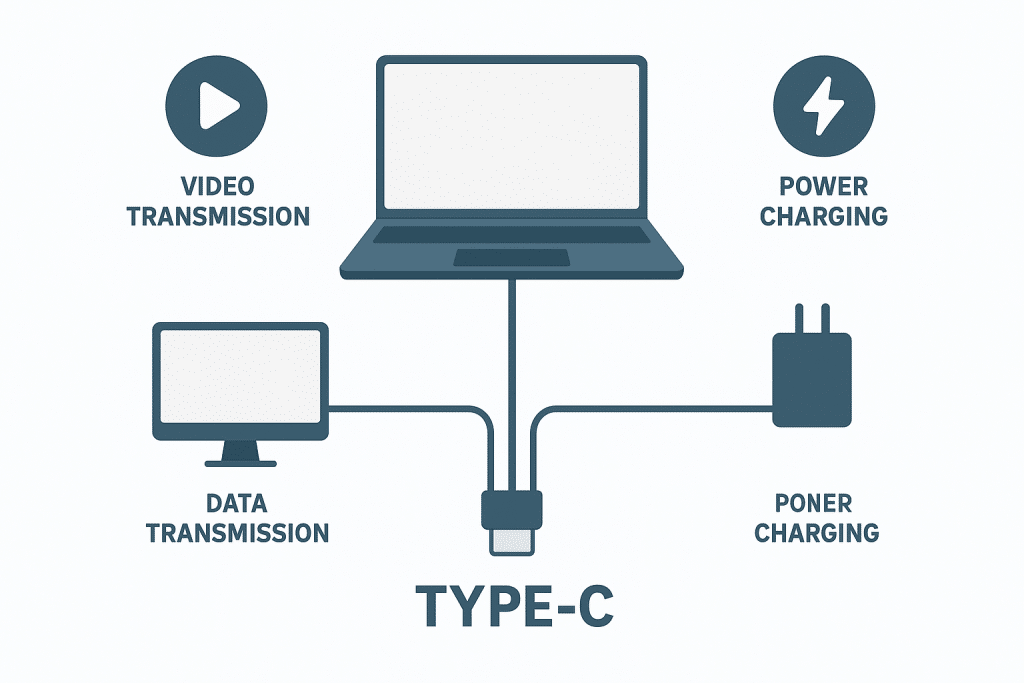

4. Powerful Power Delivery Capabilities

Type-C is not just a data interface, but also a powerful power delivery channel. By supporting the USB Power Delivery (PD) protocol, the Type-C female connector can achieve power delivery of up to 240W (USB PD 3.1 EPR standard). This defines a new paradigm for charging:

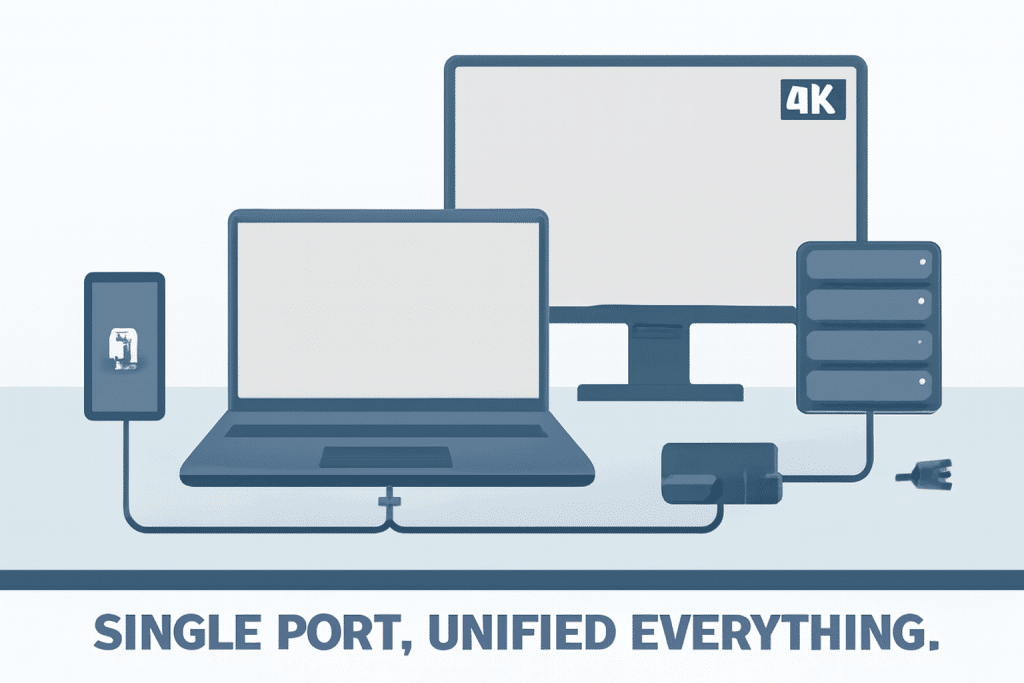

- The dream of a universal charger: Users can expect to use the same charger to charge all devices, from phones and tablets to laptops and even some high-performance gaming laptops, greatly reducing electronic waste and travel burdens.

- Reverse charging: Devices with high-capacity batteries (such as laptops) can use the Type-C female connector to provide emergency charging for other devices (such as phones and headphones), enhancing the practicality and adaptability of devices.

5. Powerful Functional Integration and Scalability

The 24 pins of the Type-C interface are given diverse functions, making it a highly integrated, multi-functional port.

- Alternate Mode: This is one of the core features of Type-C. It allows the transmission of non-USB data signals through the Type-C female connector, most notably DisplayPort Alternate Mode. This means that a single Type-C cable can be directly connected to a monitor, simultaneously transmitting video/audio signals, data, and charging, achieving a simple “one-cable” desktop solution. In addition, it supports Thunderbolt (Intel-led), HDMI, and MHL modes.

- Audio Functionality: Type-C supports digital audio output, replacing the traditional 3.5mm headphone jack, which provides more space for internal phone design and drives the development of wireless and digital wired headphones.

6. Compact Physical Size, Adapting to the Trend of Thinner and Lighter Devices

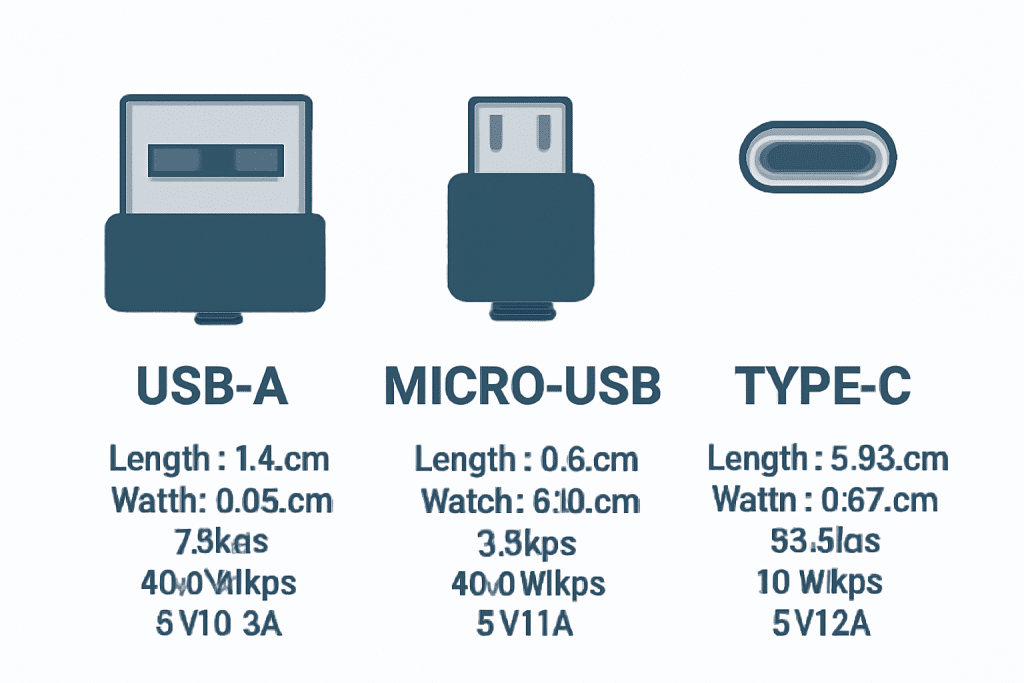

Compared to USB-A and Micro-USB, the Type-C female connector is much smaller (approximately 8.4mm x 2.6mm). This feature perfectly matches the industrial design requirements of increasingly thinner and lighter consumer electronics devices.

It allows manufacturers to fit a full range of functional interfaces into extremely limited body space, making it one of the key factors for achieving ultimate design in ultrabooks, ultra-thin tablets, and smartphones.

II. Challenges and Inherent Shortcomings of the Type-C Female Connector

Despite its significant advantages, the Type-C female connector still faces a series of challenges in technical implementation, manufacturing processes, and practical applications; these are its Achilles’ heels.

1. Structural Complexity and Manufacturing Cost

This is the core drawback mentioned in the link. The Type-C female connector integrates 24 precise and densely packed pins, several times that of Micro-USB (5 pins). This complexity has multiple impacts:

- High Machining Precision Requirements: It places extremely high demands on the precision of the connector’s molds, injection molding, and terminal stamping processes. Any minute deviation can lead to poor pin contact, unstable resistance (as described in the link), affecting signal integrity and charging efficiency.

- Higher Cost: The more complex structure means more material and more refined manufacturing processes, resulting in a significantly higher unit cost for the Type-C female connector compared to the traditional Micro-USB female connector. This cost is ultimately passed on to the price of the end device.

2. Susceptibility to Short Circuit Risk Due to Foreign Object Intrusion

This potential hazard is keenly pointed out in the link. Due to the extremely small pin spacing, the opening of the Type-C female connector easily accumulates conductive or non-conductive debris such as dust, lint, and metal shavings. Non-conductive foreign objects can cause poor contact; however, conductive foreign objects (such as metal shavings from a pocket) are more dangerous.

If they lie between the power supply pin (VBUS) and the ground pin (GND), they can easily cause a short circuit, potentially burning out the interface or even damaging the device’s motherboard. This is a side effect of its high integration, and users must ensure the ports are kept clean.

3. Mechanical Wear and Electrical Performance Degradation from Repeated Insertion and Removal

The link mentions “repeated insertion and removal increases contact resistance,” revealing a durability issue with long-term use. The elastic contact pads inside the female connector gradually experience metal fatigue with each insertion and removal, leading to weakened elasticity and reduced contact pressure with the male pins. This reduced contact pressure directly translates to increased contact resistance.

Higher resistance generates more heat (Joule heating) when transmitting large currents (such as during fast charging), accelerating port aging and creating a vicious cycle that may ultimately lead to slower charging speeds or data transmission interruptions. Although the standard specifies a 10,000-cycle insertion and removal lifespan, inferior products or improper use can significantly shorten this lifespan.

4. Protocol Compatibility and Market Chaos

This is a crucial but peripheral drawback. As a “physical carrier,” Type-C can support vastly different functionalities.

- The Existence of “Basic” Interfaces: A large number of Type-C interfaces on the market only support USB 2.0 (480Mbps) data transfer and slow charging, commonly found on some low-end devices or accessories. Users who purchase Type-C devices cannot enjoy high-speed data transfer and fast charging, resulting in a significant gap in experience.

- Inconsistent Cable Quality: A Type-C cable may only support charging, data transfer, or video output, depending on the number of internal wires and the quality of shielding. Inferior cables not only bottleneck performance but may also pose safety hazards due to non-compliance with standards.

- Consumer Confusion: As mentioned in the link, “many people are not familiar with USB-C and micro-USB.” Ordinary users find it difficult to distinguish the functional differences of Type-C interfaces on different devices, which hinders the full realization of its advantages and leads to compatibility issues.

5. Transitional Dependence on Traditional Ecosystems

The “compatibility” issue mentioned in the link refers to the large number of Micro-USB-based accessories still on the market. This forces some manufacturers to compromise when launching new products to cater to the existing user ecosystem (e.g., Samsung S7 did not adopt Type-C to adapt to Gear VR). This transition between old and new standards causes growing pains, requiring users to purchase adapters or new accessories, increasing upgrade costs.

III. Summary and Future Outlook

The Type-C female connector is undoubtedly a major innovation in interface technology. Its reversible plug-and-play convenience, powerful functional integration, high-speed data transmission, and power delivery capabilities have established a solid foundation for it to become the mainstream interface of the future. It is not only a technological advancement but also a key force driving device interconnectivity and simplifying lifestyles.

However, the manufacturing challenges brought about by its complexity, the risk of foreign object intrusion, and user experience issues caused by protocol confusion are also issues that the industry must face and solve. Solving these problems depends on:

- Strengthening standardization and certification systems: Organizations like the USB-IF need to promote stricter, more easily identifiable certification marks to help consumers easily identify the functional levels of cables and devices.

- Manufacturer quality control: Manufacturers should adhere to quality standards, using high-quality materials and precision manufacturing processes to ensure the long-term reliability of Type-C female connectors.

- Deepening consumer education: Clear product instructions will help users understand the differences between various Type-C interfaces and how to use and maintain them correctly.

Looking ahead, with the further popularization of USB4 and Thunderbolt technologies, the potential of the Type-C interface will be explored more deeply. It is expected to become a truly “universal port,” unifying the connection standards for mobile phones, computers, monitors, and even more devices.

Although challenges remain, the trend towards widespread adoption and maturity of the Type-C interface is irreversible, leading us towards a simpler, more efficient, and more interconnected digital world.