Since its release in 2014, USB Type-C connectors have become a universal interface standard for consumer electronics, industrial equipment, and in-vehicle systems with features such as full-duplex high-speed transmission, bidirectional power supply (PD 3.1 240W), and multi-function integration (DP/HDMI Alt Mode).

According to the statistics of the USB-IF Association, the global shipment of USB-C-equipped devices will exceed 5 billion units in 2023, with a penetration rate of 89%.

However, the USB-C connector is not a “monolith”. Its performance and structure are highly differentiated due to differences in application scenarios, industry standards, and protocol compatibility. For example:

- Consumer-grade cables may fail due to insufficient stamping terminal technology, resulting in PD protocol handshake failure;

- Industrial equipment needs to enhance the mating and unplugging life due to vibration environment (> 10,000 times);

- Thunderbolt 4 connectors require tight impedance control (90Ω ±5%) to guarantee 40Gbps transmission.

Based on the four dimensions of physical design, material science, electrical performance and industry certification, this paper systematically analyzes the classification logic of USB-C connectors and provides a technical decision-making framework for selection.

The Categories of USB Type-C Connectors

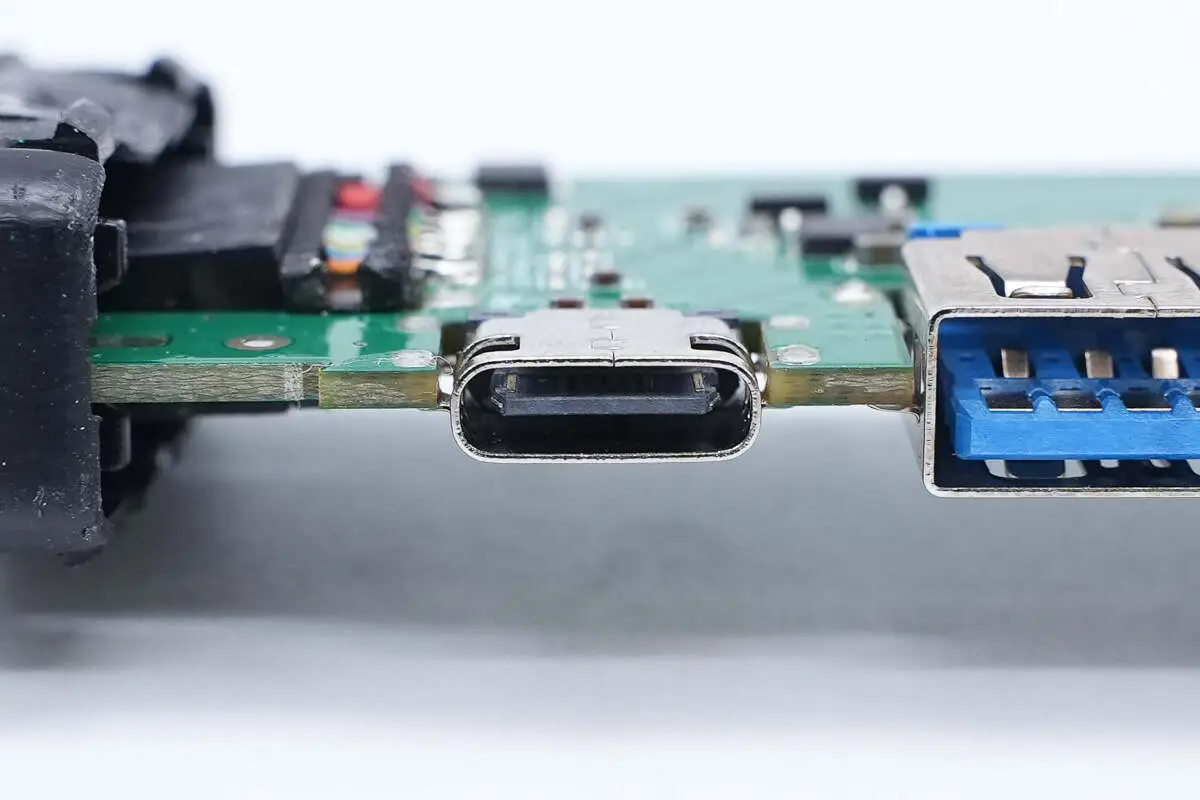

Physical Structure and Packaging Forms

| Types | Structural Features | Core Applications | Technical Details |

| Standard Direct Insertion (Vertical) | – 24 Full-Function Contacts – Plastic Housing (PBT) or Metal Shielding – Insertion/Removal Life 1,000~10,000 times | Consumer Electronics Cables, Mobile Interfaces | Supports USB 2.0 to USB4 Full Protocols, Contact Plating Thickness 0.1μm (Consumer Grade)/0.2μm (Industrial Grade) |

| Right-Angle Bend Type (Right-Angle) | -90° Folded design to reduce wire stress – Vertical/ Horizontal output direction (Vertical/Horizontal Mount) | Ultra-thin laptops, in-car entertainment systems | Insertion force 5N~20N (Compliant with automotiveAEC-Q200 standards) |

| Surface-mount (Bottom-Mount) | – PCB board mounting height ≤1.6mm – miniaturized packaging (housing size 6.5mm×2.3mm) | Smart watches, AR/VR devices | Need 4 PCB boards to ensure signal integrity (impedance control 90Ω±10%) |

| Waterproof sealing type (IP67/68) | – Silicone secondary injection molding sealing- Gold-plated contacts to prevent salt spray corrosion | Industrial robots, outdoor surveillance equipment | Passing 96 hours of salt spray test (IEC 60529 standard), plug-and-play life > 5,000 times |

______

Material process and reliability design

Contact Process

| Process Type | Manufacturing Method | Performance Advantages | Applicable scenarios |

| Stamped terminals | Copper alloy sheet stamped and formed, low cost | Impedance30mΩ, supports3Acurrent | USB 2.0 cables, low-speed peripherals |

| Machine-tapped terminals (Machined) | Precision machine-tapped copper bars, mirror-polished contact surfaces | Impedance≤20mΩ,supports5A~240W EPR | Fast charging cables, Thunderbolt 4 High-speed interface |

| Dual-row spring pin | Dual-row elastic contacts enhance contact stability | Insertion/Removal Life >15,000 times | Hot-swap server SSD、Data center |

2. Case material

| Material type | Features | Typical Applications |

| PBT/Nylon Plastic | Temperature Resistance120℃~150℃, Excellent Insulation, Low Cost | Mobile and Tablet Interfaces |

| Zinc alloy shielded housing | EMI shielding effectiveness >60dB, strong heat dissipation | Industrial control equipment, lightning4 expansion dock |

| Titanium alloy lightweight | Strength/Weight ratio is better than stainless steel, corrosion-resistant | Aerospace equipment, military communication terminals |

______

Electrical Performance and Protocol Support

1.Transmission performance classification

| Level | Protocol Support | Speed/Power | Signal Integrity Requirements |

| Basic Type (USB 2.0) | Only USB 2.0 | 480Mbps, 7.5W | Single-ended signal, no impedance control |

| Full-Featured (USB4) | USB4/Thunderbolt 4, DP Alt Mode | 40Gbps, 240W EPR | Differential Pair Impedance90Ω±10%,Coplanarity≤0.1mm |

| Photonic-Hybrid Type (Future) | USB4 V2.0 +Fiber Optic | 80Gbps(Copper Cable)+>100Gbps(Fiber Optic) | Copper Cable Power Supply+Fiber Optic Data Transmission, No Electromagnetic Interference |

2. High-Frequency Optimization Design

Impedance Matching: Differential Pair Length Tolerance±0.05mm, to avoid signal reflection.

Crosstalk Suppression: Add grounding isolation pins between adjacent contacts (e.g., Intel Thunderbolt 4 design)

Active Cable: Built-in Retimer chip compensates for signal attenuation (supports 2-meter 40 Gbps transmission).

______

Industrial Standards and Certification Systems

| Standard Certification | Testing Requirements | Applicable Fields | Representative manufacturers |

| USB-IF TID Certification | Insertion/Removal Life >10,000times, Protocol Compatibility Testing | Consumer electronics brand accessories | Anfei, Foxconn |

| IEC 61076 Industrial Grade | -40℃~125℃High and low temperature cycle, 96 hours salt spray test | Industrial automation, energy equipment | TE Connectivity, Molex |

| AEC-Q200 Automotive Grade | 20G mechanical vibration, 85℃/85% humidity 1000 hour test | New energy vehicles, in-vehicle entertainment systems | JAE, Hirose |

| MIL-STD-810 Mil-Spec | Electromagnetic Pulse (EMP) Protection, -55℃~150℃ Extreme Temperature Range | Military Communications, Satellite Equipment | Amphenol、Souriau |

______

Vertical Industry Application Cases

1. Medical Electronics

Antimicrobial Erosion Resistance: The housing is made of PEEK material, resistant to ethylene oxide sterilization.

Anti-misoperation design: Magnetic locking interface (e.g., Da Vinci surgical robot power module).

2. Intelligent Vehicle

High-speed Interconnection: Supports automotive Ethernet (1000BASE-T1) and camera video stream (MIPI CSI-2).

Vibration Protection: Zinc alloy casing, THT Through-hole welding, withstands vehicle shocks (>50G impact).

3. Innovations in Consumer Electronics

No-port design: OPPO scroll screen phone hidden Type-C interface.

Self-healing technology: Nano-coated contacts (laboratory stage), automatically restore conductivity after oxidation.

______

Selection Decision Framework

Performance priority:

Speed-sensitive type: choose USB4+spindle terminals with metal shielding.

High-reliability scenarios: choose industrial-grade certification+phosphor bronze contacts.

Cost control:

Consumer-grade: stamped terminals+PBThousing (cost<0.5USD/port)。

Automotive grade: Zinc alloy+Turned terminals (cost >3 USD/port).

Supply chain strategy:

Avoid single sourcing (e.g., Thunderbolt chip dependency on Intel supply).

Prioritize USB-IF-certified suppliers (reduce compatibility risks).

Future Technology Trends

USB4 V2.0:2024 year commercialization, PAM3 modulation achieves 80Gbps speed.

Wireless substitution: Near-field wireless charging (Qi2)+ Ultra-wideband (UWB) data transmission, gradually replacing physical interfaces.

Smart Connector: Built-in MCU chip, achieving protocol adaptation and dynamic power consumption adjustment.

Summary

USB Type-C connector classification requires a four-dimensional cross-evaluation including physical structure, material reliability, electrical performance, and industry certifications.

Selection should focus on application scenarios (consumer, industrial, and military), cost thresholds, and future compatibility, while also paying attention to the evolution of USB-IF and ISO standards to adapt to technological changes, such as high-speed and wireless advancements.