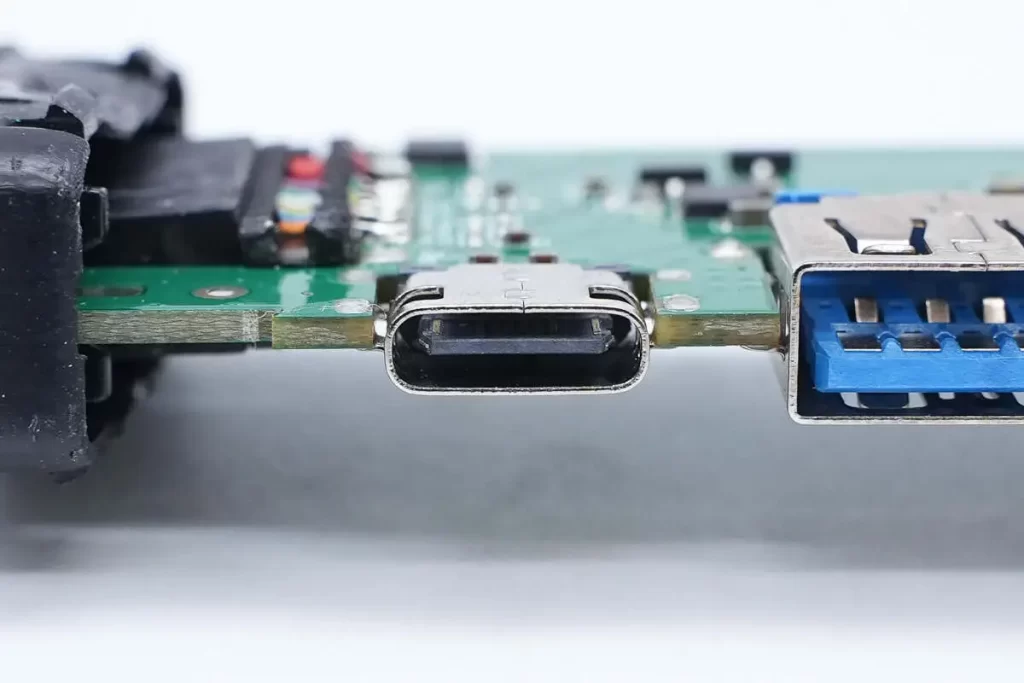

In industrial automation equipment, the protective standards that USB type C PCB connector must meet are significantly more stringent than those in the consumer electronics sector, primarily to address the challenges of harsh environments. The table below summarizes these critical protective standards and requirements for a quick overview.

| Protection Category | Core Standard / Rating | Significance and Requirements in Industrial Environments |

|---|---|---|

| Enclosure Protection (IP Code) | IP67 / IP68 / IP69K | Prevents ingress of dust and liquids. IP67 withstands temporary immersion (1 meter, 30 min). IP68 offers protection against continuous immersion. IP69K protects against high-pressure, high-temperature water jets, crucial for washdown areas in food & beverage or pharmaceutical plants. |

| Mechanical Durability | ≥ 10,000 mating cycles | Far exceeds consumer-grade standards (typically below 5,000 cycles). Meets the demands of frequent debugging, maintenance, and peripheral connection in industrial settings, ensuring long-term connection stability. |

| Vibration & Shock | IEC 60068-2-6/27, USCAR-2, LV214 | Ensures connectors maintain reliable contact under severe vibration and shock. For example, USCAR-2 specifies rigorous random vibration profiles and thermal cycling tests to simulate automotive/transport environments. |

| ESD Protection | IEC 61000-4-2, Level 4 | Protects internal chips from damage due to electrostatic discharge from personnel or equipment. Industrial ESD risks are higher; typically requires ≥8kV contact discharge and ≥15kV air discharge protection. |

| Chemical & Corrosion Resistance | Salt Spray Test ≥ 48 hours (per ASTM B117 or ISO 9227) | Resists corrosive gases, liquids, or salt sprays present in industrial environments (e.g., coastal areas, chemical plants), preventing corrosion of metal contacts and preserving electrical performance. |

| Extended Temperature Range | -40°C to +85°C / +105°C | Adapts to extreme temperature fluctuations in industrial sites, from cold storage to areas near high-temperature machinery, ensuring stable operation. |

| Flammability | UL94 V-0 | The housing material must have a high flame-retardant rating to prevent the spread of fire, which is a critical safety requirement in many industrial facilities. |

Beyond the Standards: Technologies and Designs for Achieving Protection

Meeting these standards requires deliberate design and material selection for industrial-grade USB-C connectors:

- Robust Construction and Sealing Technologies: Industrial USB-C connectors employ more secure latching mechanisms (screw-locks, push-pull, or robust snap-in designs) and utilize stainless steel shells and high-grade engineering plastics (like PBT) to withstand vibration and physical stress. High IP ratings are achieved through precision-molded seals, rubber O-rings, or Liquid Injection Molding (LIM) to create a complete seal against dust and liquids. The cable exit often includes a strain relief boot to prevent cable breakage.

- Precision Circuit Protection Schemes: The 24-pin USB-C interface has varied protection needs per line. Industrial applications require precise selection of protection devices:

- High-Speed Data Lines (SuperSpeed TX/RX): Require ultra-low capacitance TVS diodes (e.g., <0.5pF) to prevent high-speed signal integrity degradation.

- Power Line (VBUS): Carries higher power and needs TVS diodes with high clamping voltage and power capacity to handle power surges and transients. A resettable fuse (PPTC) is often added for overcurrent protection.

- Configuration Channel (CC) and Sideband Use (SBU): Can use general-purpose TVS diodes that balance performance and cost.

- Integrated Protection ICs: Advanced designs may incorporate combinational protection arrays that safeguard multiple lines (e.g., data + CC) in a single package, saving board space.

- EMI/RFI Shielding: Effective 360-degree metal shell shielding and cable shielding with a low-transfer impedance are essential to prevent electromagnetic interference from disrupting sensitive industrial control systems and to comply with EMC standards like IEC 61000-6-2/4.

Practical Guide for Procurement and Selection of USB type C PCB connector

For procurement specialists and engineers, consider the following during selection:

- Define the Application Scenario Clearly: Identify the specific environment—will it face washdown, high vibration, extreme temperatures, or chemical exposure? This determines the required IP rating, vibration test grade, operating temperature range, and corrosion resistance.

- Verify Key Parameters and Documentation:

- Protection Rating: Must be explicitly marked as IP67 or higher.

- Mating Cycle Life: Confirm it reaches 10,000 cycles or more.

- Operating Temperature: The range must cover your application’s extremes.

- Certifications and Test Reports: Prioritize products that explicitly mention compliance with USCAR-2, LV214 vibration tests, or provide 48+ hour salt spray test reports. Request Declarations of Conformity for relevant standards.

- Evaluate Supplier Expertise: Prioritize brands specializing in industrial connectors (e.g., Amphenol, TE Connectivity, Molex, Hirose, Phoenix Contact). They possess a deeper understanding of harsh environment demands. Assess their ability to provide detailed technical drawings, 3D models, and application support.

- Consider the Total Cost of Ownership (TCO): While industrial-grade connectors have a higher unit price, they reduce long-term costs by minimizing downtime, maintenance, and field failures. Investing in quality upfront protects more valuable system components.

This expanded information should provide a more comprehensive understanding of the requirements for industrial-grade USB type c pcb connector. If you have more specific questions regarding particular industrial scenarios or standards, I am happy to offer further analysis.