In today’s trend of electronic products becoming increasingly thinner, lighter, and higher-density, every millimeter of space is crucial.

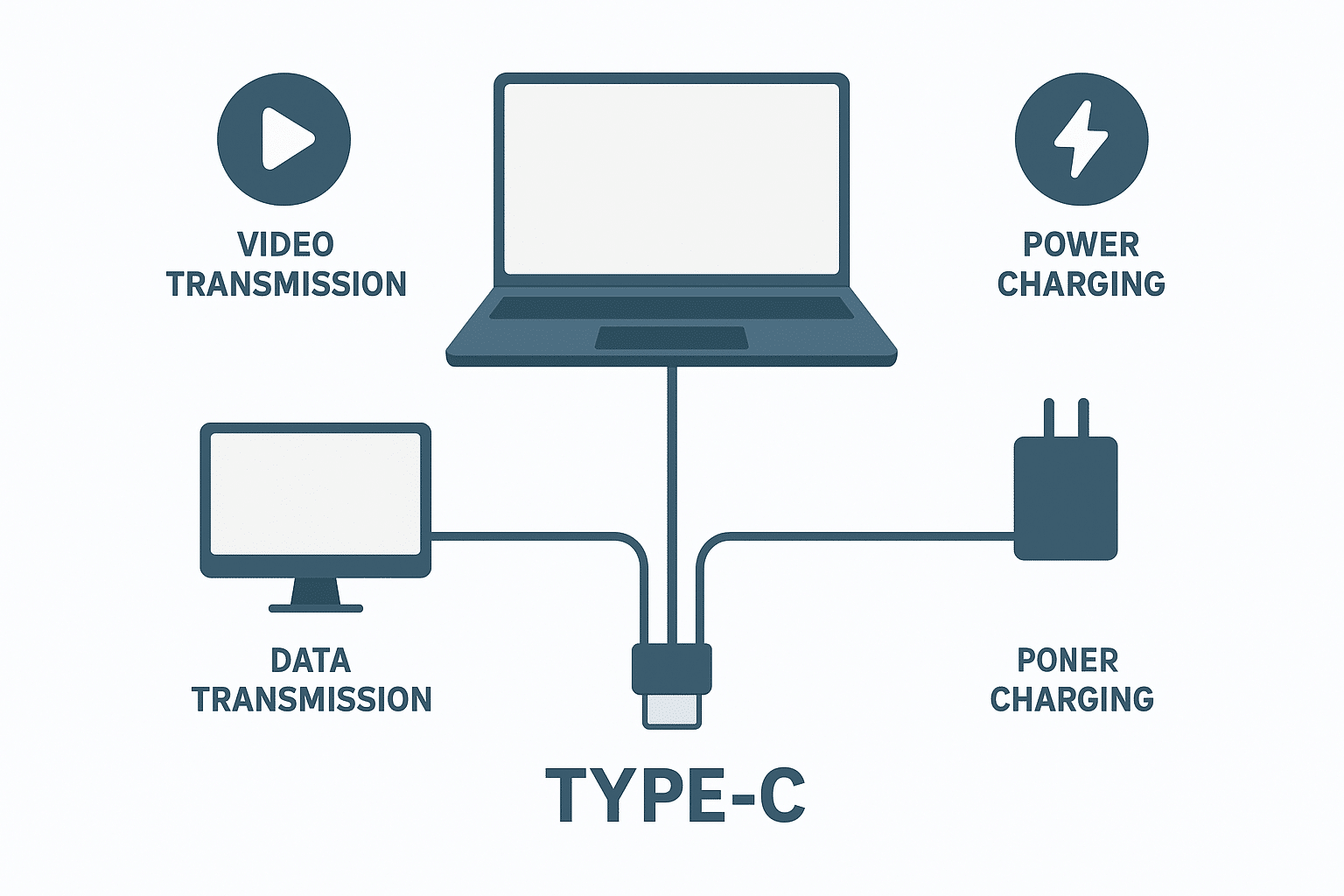

The USB Type-C interface, with its reversible insertion, high speed, and powerful power delivery capabilities, has become standard in modern devices. Its Surface Mount Technology (SMT) Right Angle variant is an engineering masterpiece that solves the challenge of efficient interconnection within compact spaces.

This article will delve into the design advantages, technical details, and how this key component reshapes product internal layout.

I. Definition and Core Design Advantages

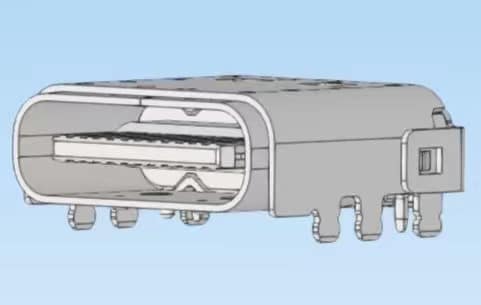

The USB Type-C SMT Right-Angle connector specifically refers to a connector whose terminals are surface-mounted to the PCB, and whose mating direction is 90 degrees perpendicular to the PCB plane. Compared to traditional through-hole or vertical SMT connectors, it brings revolutionary space optimization:

- Extremely Low Z-Axis Height Savings: This is its most significant advantage. 1. Right-angle design: This design places the connector body parallel to the PCB board, rather than perpendicular to it, significantly reducing the space occupied by the interface along the device’s thickness (Z-axis). This is crucial for the design of ultra-thin laptops, tablets, smartphones, and various portable peripherals.

- Optimized Internal Layout and Airflow: In systems with limited motherboard space (such as mini PCs, gaming laptops, and smart TV core boards), right-angle connectors allow cables to exit horizontally from the side of the motherboard, rather than bending upwards. This streamlines cable routing, avoids interference with other tall components (such as heatsinks and batteries), and helps optimize airflow and improve assembly efficiency.

- Enhanced Mechanical Reliability: When cables are connected horizontally, the resulting stress is primarily applied to the connector housing’s reinforcement structure, rather than directly to the PCB solder joints. A well-designed right-angle design better manages and distributes insertion and removal stress and fatigue caused by cable sway, thus providing a more reliable long-term connection than a vertical interface under frequent insertion/removal or device movement scenarios.

II. Key Technical Specifications and Design Considerations

A high-quality USB Type-C SMT right-angle connector is far more than a simple bend; its design involves a deep integration of precision mechanics, electrical performance, and manufacturing processes.

- Pin Configuration and High-Speed Signal Integrity:

- A complete USB Type-C interface contains 24 pins, supporting USB 2.0, USB 3.2/4 Gen high-speed data pairs (TX/RX), sideband usage (SBU), configuration channel (CC), and a powerful USB Power Delivery (PD) power pin.

- The right-angle design presents significant challenges to high-speed signal links, especially USB4 signals of 20Gbps and above. The bent path can introduce impedance discontinuities and signal loss. Therefore, high-end connectors employ precisely designed differential pair wiring internally and may integrate impedance matching structures to ensure tight impedance control (typically targeting 85Ω or 90Ω differential impedance) at the corners to meet USB-IF certification requirements.

- Mechanical Structure:

- Housing and Tongues: Typically made of high-strength, highly abrasion-resistant engineering plastics (such as LCP), ensuring a lifespan of tens of thousands of mating cycles. The internal metal terminal layout of the tongues must be precise to ensure stable contact with the male connector.

- Shielding and Grounding: The entire connector requires a complete metal shielding housing to achieve excellent electromagnetic interference (EMI) and radio frequency interference (RFI) suppression. The SMT pad design includes numerous grounding pins, ensuring that the shielding housing forms a low-impedance, fully covered “Faraday cage” with the PCB ground plane, protecting internal high-speed signals from interference and preventing signal radiation leakage.

- Positioning and Fixing: In addition to the main SMT solder pads, the connector body is typically designed with robust positioning posts or retaining claws, which are initially fixed to the PCB before reflow soldering via perforations or snap-fit methods. A large grounding solder flange is provided at the bottom to provide extremely strong resistance to mechanical stress and torque.

- SMT Process Compatibility:

The connector package must conform to standard SMT placement and reflow soldering processes. The solder pad layout must consider stencil opening design to ensure uniform solder paste distribution. The material must be able to withstand the high temperatures of lead-free soldering processes (approximately 260°C peak) to prevent deformation of the plastic housing or oxidation of the terminals.

III. Core Application Scenarios

- Portable Computing Devices: The edge of the motherboard in ultrabooks and 2-in-1 tablets is a typical application for right-angle Type-C connectors. It allows for thinner devices while accommodating multiple full-featured interfaces.

- High-End Motherboards and Dockyards: On desktop motherboards or laptop docking stations, right-angle connectors are used for rear I/O panels or internal jumper connections, resulting in a cleaner layout and easier cable management.

- Consumer Electronics and Display Devices: Signal boards in ultra-thin TVs and monitors, as well as digital cameras and handheld gaming devices, are used to save valuable internal space.

- Industrial and Embedded Systems: In space-constrained industrial PCs and embedded devices, right-angle connectors provide a reliable and space-saving external data and power path.

IV. Selection and Design Considerations

Engineers must comprehensively consider the following when selecting a connector:

- Performance Level: Clearly define the highest protocol standard that needs to be supported (e.g., USB 3.2 Gen 2×1, USB4).

- Current Carrying Capacity: Based on PD protocol requirements, select a terminal design that can support 5A or even higher currents.

- Stacking Height: Confirm the precise dimensions from the bottom of the connector body to the top of the socket to match the openings and internal space constraints of the device housing.

- Certification: Prioritize products that have passed USB-IF certification to ensure compatibility and reliability.

V. Future Outlook

As USB4 and the upcoming USB4 v2.0 standards drive data transfer rates towards 80Gbps and even higher, the requirements for connector signal integrity will increase exponentially.

Future USB Type-C SMT right-angle connectors will further integrate more advanced materials (such as lower-loss dielectric materials), more sophisticated common-mode rejection designs, and may be more tightly integrated with integrated protection circuitry (such as ESD suppressors).

Meanwhile, the use of environmentally friendly and recyclable materials will also become an important trend in sustainable manufacturing.

Conclusion

The USB Type-C SMT Right Angle connector is an epitome of modern electronic engineering design wisdom. It perfectly illustrates how to balance extreme physical size constraints, demanding high-speed electrical performance, and stringent mechanical reliability requirements within a small space.

As an indispensable bridge to achieving both thinner and more functional devices, its continued evolution will continue to lay a solid foundation for the next generation of more powerful and compact electronic devices.