Choosing the right usb connector supplier is a critical business decision that directly impacts product quality, reliability, and time-to-market.

This guide provides a systematic approach to supplier selection, covering technical capabilities, quality assurance, supply chain stability, and strategic alignment.

By following this framework, engineering and procurement professionals can mitigate risks, optimize costs, and establish partnerships that support long-term business objectives in an increasingly complex interconnect landscape.

Define Your Requirements Clearly

Before evaluating potential suppliers, you must establish clear technical and commercial requirements. This foundational step ensures alignment between your needs and a supplier’s capabilities.

Technical specifications should include connector type (wire-to-wire, wire-to-board, board-to-board, circular, rectangular), electrical parameters (voltage, current, frequency), mechanical requirements (size, configuration, mounting style), and environmental conditions (temperature range, moisture exposure, vibration resistance) .

For applications in harsh environments—such as automotive, aerospace, or industrial settings—you may need specialized features like IP67/IP68 waterproof ratings or resistance to extreme temperatures .

Commercial considerations include projected volumes, target pricing, required lead times, and flexibility for engineering changes. Clearly document whether you need standard off-the-shelf components or customized solutions, as this significantly impacts supplier selection .

Research Potential USB Connector Suppliers

With requirements defined, identify potential suppliers through multiple channels:

- Online platforms like Alibaba, ThomasNet, and specialized electronics marketplaces (LCSC, Findchips) offer broad supplier access with user reviews and ratings .

- Industry trade shows (Electronica, PCIM Europe, Automotive Engineering Expo) provide opportunities for face-to-face engagement with global suppliers and hands-on product evaluation .

- Manufacturer websites of leading brands (TE Connectivity, Amphenol, Molex, Hirose) provide detailed technical specifications and documentation .

- Industry associations (Connector Suppliers Association, IPC) maintain directories of reputable manufacturers .

- Peer referrals from industry colleagues often yield trusted recommendations based on actual experience .

Consider both global giants and specialized regional suppliers. While large corporations offer extensive resources and standardization, smaller specialized suppliers like our company Vistar Electronics may provide more flexible customization, faster response times, and cost advantages for specific applications .

Evaluate Technical Capabilities and Quality Systems

A supplier’s technical expertise and quality management systems are paramount for consistent performance.

Quality certifications provide objective evidence of a supplier’s commitment to quality. Look for ISO 9001 (Quality Management System), ISO 14001 (Environmental Management System), IATF 16949 (automotive quality standard), and industry-specific certifications like AS9100 for aerospace . These certifications indicate adherence to internationally recognized processes and continuous improvement frameworks .

Testing capabilities demonstrate a supplier’s ability to validate product performance. Reputable suppliers conduct comprehensive testing such as:

- Electrical performance tests: Insulation resistance, contact resistance, withstand voltage, and temperature rise tests .

- Mechanical tests: Insertion/extraction force, vibration, mechanical shock, and durability testing through mating cycles .

- Environmental tests: Salt spray corrosion resistance, temperature and humidity cycling .

- Environmental Compliance: Verification of RoHS, REACH, and Other Regulatory Requirements.

Technical expertise should extend beyond basic manufacturing. Evaluate the supplier’s design capabilities, material science knowledge (understanding of copper alloys, plating technologies), and experience with similar applications . Suppliers with strong engineering support can provide valuable guidance during design-in phases and help optimize connector selection for your specific application .

Assess Manufacturing and Supply Chain Capabilities

Production capabilities directly impact quality consistency, scalability, and delivery reliability.

Manufacturing infrastructure including precision molding, stamping, plating, and assembly equipment should be modern and well-maintained. Automated production lines typically deliver higher consistency than manual operations . Consider whether the supplier controls manufacturing processes vertically (from raw materials to finished goods) or relies heavily on outsourcing, as this affects quality control and supply chain transparency .

Capacity planning should align with your volume requirements and growth projections. Discuss current utilization rates and expansion capabilities to ensure the supplier can scale with your business .

Supply chain resilience has become increasingly important. Evaluate the supplier’s raw material sourcing strategies, inventory management practices, and geographic diversity of manufacturing facilities.

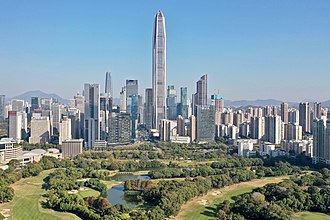

Regions like China’s Zhejiang and Guangdong provinces(Shenzhen) host industrial clusters that offer cost efficiency and scalability, but also consider geopolitical and logistics factors.

Analyze Cost Structures and Value Propositions

While price is important, the total cost of ownership (TCO) includes multiple factors beyond unit price.

Pricing transparency should extend to tooling costs, minimum order quantities (MOQs), payment terms, and potential volume discounts . Be wary of prices significantly below market averages, as this may indicate compromised quality or materials .

Value-added services like design support, prototyping, testing, and technical documentation contribute to TCO reduction by accelerating development cycles and minimizing field failures .

Lifecycle considerations include product longevity, failure rates, and replacement part availability. A slightly higher initial cost may be justified by superior reliability, especially for critical applications where connector failure would have severe consequences .

Review Support Services and Relationship Factors

The quality of supplier relationship management significantly impacts project success, especially for long-term or complex engagements.

Technical support accessibility during design, prototyping, and production phases is crucial. Evaluate response times, documentation quality, and the supplier’s willingness to collaborate on solving technical challenges .

Communication effectiveness includes language capabilities, cultural alignment, and designated points of contact. During evaluations, note response timeliness and completeness—this often indicates how the supplier will communicate during actual projects .

After-sales service encompasses warranty policies, return processes, and ongoing technical assistance. Reliable suppliers stand behind their products with clear warranties and responsive support structures .

Make the Final Decision

With comprehensive data collected, systematically compare suppliers against weighted criteria aligned with your priorities.

Connector Supplier Evaluation Matrix

| Evaluation Criteria | Weighting Factor | Supplier A | Supplier B | Supplier C |

| Technical Capability | 25% | |||

| Quality Systems | 20% | |||

| Pricing/Value | 20% | |||

| Supply Reliability | 15% | |||

| Support Services | 10% | |||

| Flexibility/Responsiveness | 10% | |||

| Total Score | 100% |

Sample testing provides the most direct evidence of product suitability. Order samples for rigorous validation under conditions that simulate your actual application, including environmental stresses and lifetime testing .

Reference checks with existing customers, particularly those in similar industries or applications, offer insights into real-world performance and relationship quality .

Site visits (virtual or in-person) allow firsthand assessment of facilities, processes, and quality culture. Many reputable suppliers welcome customer audits as demonstrations of transparency and capability .

Implementation and Continuous Improvement

Supplier selection is not a one-time event but the beginning of an ongoing relationship.

Initial orders should be structured with clear specifications, inspection protocols, and acceptance criteria. Gradually scale volumes as confidence builds .

Performance monitoring should track key metrics like on-time delivery, quality acceptance rates, and incident frequency. Establish regular business reviews to discuss performance, address issues, and identify improvement opportunities .

Relationship development through open communication, fair dealing, and strategic alignment creates foundation for continuous improvement and potentially preferential treatment during market constraints .

Conclusion

Selecting the right usb connector supplier requires methodical evaluation across technical, quality, commercial, and relational dimensions.

By investing time in thorough due diligence and looking beyond price to total value, organizations can establish partnerships that deliver competitive advantage through improved product reliability, faster time-to-market, and lower total cost of ownership.

The framework presented here provides a structured approach to this critical business decision, adaptable to specific organizational needs and application requirements.