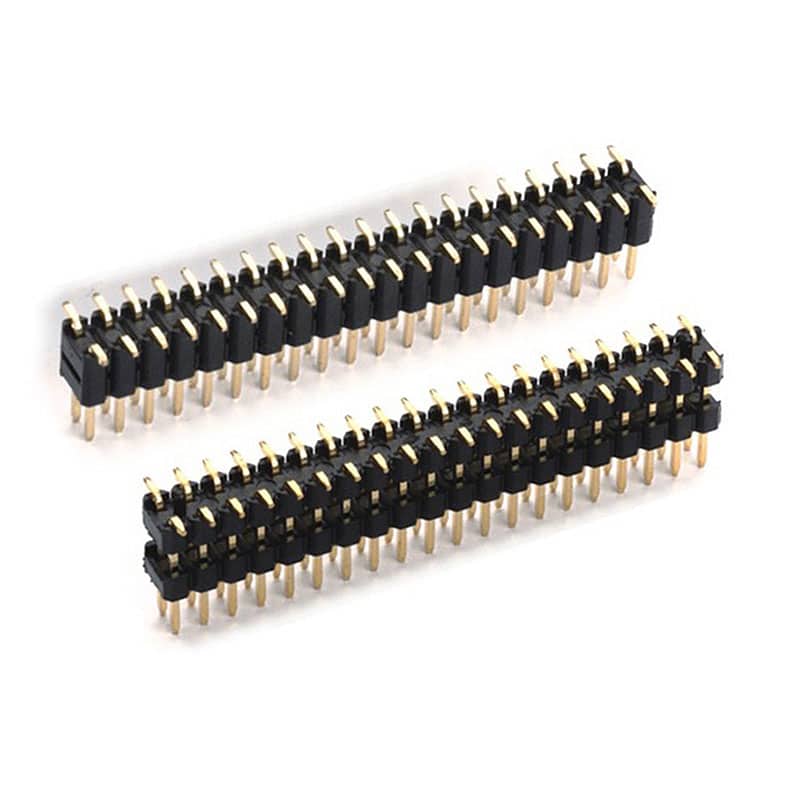

The 2.54mm pitch 40 pin connector header (also known as the Bergstik connector) is a classic and versatile board-to-board connection solution. Below is a detailed overview of its core features, application selection, and purchasing considerations.

Core Features and Advantages

- Breakaway Design: The 40 pin connector header can be easily manually separated along pre-molded breakpoints, allowing it to be snapped into smaller pin-count configurations (e.g., 2×20, 1×40, or smaller units) as needed. This offers exceptional flexibility for PCB layout and component inventory management.

- Standard Pitch: The 2.54mm (0.1-inch) pin spacing is an industry standard, ensuring perfect compatibility with breadboards, Arduino, Raspberry Pi, and various other development boards and standard PCBs.

- Diverse Configurations: Available in multiple styles including single-row, double-row, straight pins, and right-angle pins, as well as different heights (e.g., 8.5mm), to suit various spatial and connection orientation requirements.

- Reliable Electrical Performance: Typically rated for 3A current and 250V AC/DC, with an insulation resistance of ≥1000MΩ and a contact resistance of ≤20mΩ, meeting the needs of most low-voltage applications.

- Robust Construction: High-quality versions feature pins made from phosphor bronze with thick gold or tin plating, housed in high-temperature resistant PA6T or PBT plastic shells, ensuring excellent conductivity, durability, and solderability.

Selection Guide: Male vs. Female 40 Pin Connector Headers

| Feature Dimension | Male Header (Pin Header) | Female Header (Socket Header) |

|---|---|---|

| Physical Form | Rigid, pin-like contacts | Cylindrical sockets with receptacles |

| Mounting Style | Straight (vertical) or right-angle | Straight or right-angle, corresponding to the male header |

| Typical Application | Usually soldered onto the main PCB | Often soldered onto a daughter board to mate with a male header; or used with cable assemblies (e.g., IDC connectors) |

| Protective Role | Pins are relatively exposed | When mated, provides some protection; some models feature guide slots and locking mechanisms for enhanced connection stability and anti-vibration. |

Application Scenarios and Selection Points

- Application Scenarios: Widely used in development boards, core control boards, LCD display modules, sensor modules, and for interconnections between stacked multi-layer PCBs requiring reliable, removable connections.

- Selection Points:

- Pin Count & Arrangement: Determined by the number of signals; common options are 1x40P (single-row 40-pin) or 2x20P (dual-row 20-pin).

- Mounting Type: Through-hole (THT) or Surface-mount (SMT). THT offers higher mechanical strength, while SMT is better suited for automated assembly.

- Pin Length & Profile Height: Select the appropriate height based on the required clearance between PCBs.

- Material & Plating: Opt for connectors with phosphor bronze contacts and thick gold or tin plating for optimal conductivity and corrosion resistance. High-temperature plastic housings (e.g., PA6T, PBT) ensure stability during reflow soldering.

- Additional Features: Consider headers with polarizing keys, locking clips, or friction locks for high-vibration environments or critical connections.

Procurement and Supply Chain Considerations

- Cost Factors: Pricing is influenced by order quantity, plating quality, and brand. Unit cost can drop to between $0.01 and $0.10 for large-volume purchases.

- Supplier Selection: Numerous reliable manufacturers and suppliers exist globally, including established distributors like Samtec, TE Connectivity, Amphenol, as well as many quality-focused manufacturers in regions like Shenzhen and Dongguan.

- Quality Certifications: Ensure products comply with environmental directives like RoHS and REACH. Some suppliers provide 100% factory testing for critical parameters.

- Customization Services: Many suppliers offer ODM/OEM support, allowing customization of parameters such as specific heights, colors, plating types, or packaging based on provided drawings or samples.

- Handling & Storage: Purchase from suppliers who use proper anti-static and moisture-barrier packaging to prevent oxidation of contacts, especially for gold-plated versions.

Summary

The 2.54mm 40 pin connector header is the “universal key” in electronics design, perfectly balancing flexibility, cost-effectiveness, and reliability. Its standardized dimensions and breakaway nature make it a fundamental component for prototyping, production, and interconnecting modular systems.

By carefully considering the electrical requirements, mechanical constraints, and sourcing options outlined above, you can effectively select and integrate this essential connector into your projects.

Extended Insight:

For robust applications, consider using shrouded or box-style female headers which offer better pin alignment and physical protection. Additionally, for frequent mating/unmating cycles, choosing headers with higher cycle life ratings (e.g., 5,000+ cycles) and superior plating is advisable. Always verify the mating compatibility between different brands, as tolerances can vary slightly. In automated assembly processes, tape-and-reel packaging for SMT headers significantly improves placement speed and efficiency.

We hope this comprehensive information aids in your understanding and selection of this connector type. If you have more specific questions regarding a particular application, we can provide deeper analysis.