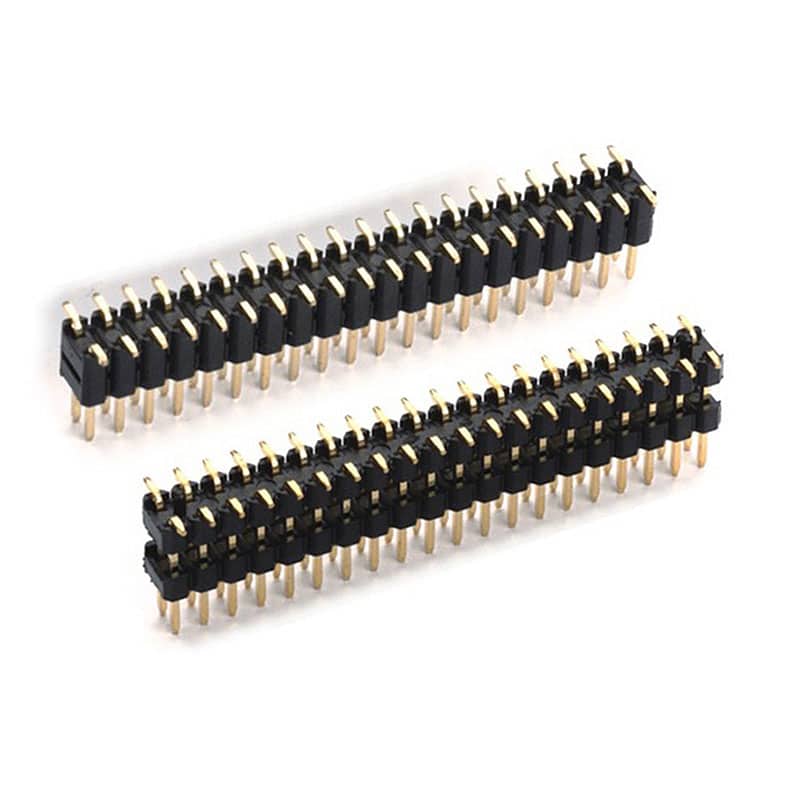

Board-to-Board Connectors

Board to board connectors, or inter-board connectors, are electrical interface components used to connect two printed circuit boards (PCBs) or other electronic modules. These connectors allow the transfer of signals, power, and data between the connected boards, enabling the integration of different functionalities and creating more complex electronic systems.

The main pitches of board-to-board connectors are 0.4mm, 0.5mm, 0.635mm, 0.8mm, 1.00mm, and 1.27mm.

Board to Board Connector Types

Board-to-board connectors come in various types, including through-hole, surface mount, and press-fit connectors. They can be classified based on pin arrangement, such as single-row, dual-row, and stacked connectors. Some connectors also offer additional features like shielding, locking mechanisms, and polarization to ensure proper alignment and prevent accidental disconnection

how to remove circuit board connectors

Here are some general steps for removing circuit board connectors:

1. Identify the connector type:

– Determine if the connector is a through-hole type or a surface-mount type.

– Examine the connector to see if it has any locking or latching mechanisms that need to be released first.

2. Prepare the work area:

– Ensure you have the proper tools on hand, such as a soldering iron, desoldering tool, tweezers, and a magnifying glass (if working with small components).

– Provide a clean, well-lit, and static-safe work surface.

3. Desolder the connector (for through-hole connectors):

– Heat the solder joints on the connector pins using a soldering iron.

– Use a desoldering tool or solder wick to remove the molten solder from the holes.

– Gently rock the connector back and forth while lifting it off the board.

4. Desolder the connector (for surface-mount connectors):

– Heat the solder joints on the connector’s pads using a soldering iron or hot air rework station.

– Use a desoldering tool or tweezers to carefully lift the connector off the board.

5. Clean the board:

– Remove any remaining solder residue from the board using a solder wick or desoldering pump.

– Clean the board surface with isopropyl alcohol and a clean, lint-free cloth to remove any flux or contaminants.

6. Inspect the board:

– Ensure that all the solder pads or holes are clean and undamaged.

– Check for any lifted or damaged traces on the board.

7. Prepare the new connector (if replacing):

– Align the new connector with the board’s pads or holes.

– Solder the connector in place, ensuring that all the joints are properly formed.

Remember to take appropriate safety precautions, such as using a fume extractor and wearing anti-static gloves, when working with circuit boards and soldering. Additionally, consult the manufacturer’s instructions or schematics for specific guidance on removing and replacing connectors for your particular circuit board.

Applications

Board-to-board connectors are connector products with the strongest transmission capacity among all connector product types. They are mainly used in power systems, communication networks, financial manufacturing, elevators, industrial automation, medical equipment, office equipment, home appliances, military manufacturing, and other industries.