Quartz Crystal Oscillators

The quartz crystal oscillator is a resonant device made using the piezoelectric effect of quartz crystals, and is capable of generating high-precision oscillation frequencies to provide stable clock signals for electronic systems.

Working Principle

Piezoelectric Effect:

When a quartz crystal is subjected to mechanical stress, it generates an electric charge on its surface. Conversely, when an electric field is applied across the crystal, it undergoes mechanical deformation. This mutual conversion between mechanical stress and electric charge is known as the piezoelectric effect. When an alternating voltage is applied to the electrodes of a quartz crystal, the crystal vibrates mechanically, and these vibrations, in turn, produce an alternating electric field.

Resonance Principle:

When the frequency of the applied alternating voltage matches the natural frequency of the quartz crystal, piezoelectric resonance occurs. At this point, the amplitude of mechanical vibration increases sharply, and the current in the circuit reaches its maximum. A quartz crystal oscillator is designed by selecting an appropriate quartz crystal and circuit parameters to ensure stable oscillation at the crystal’s natural frequency.

Structural Components

1.Quartz Crystal Blank (Wafer):

A thin slice cut from a quartz crystal at a specific orientation angle. The cutting method, geometry, and dimensions determine key parameters such as resonant frequency and temperature stability.

2.Electrodes:

Silver coatings on two opposite surfaces of the quartz wafer serve as electrodes to connect with external circuits for applying an electric field or detecting charges.

3.Encapsulation Housing:

Typically made of metal, glass, ceramic, or plastic to protect the quartz wafer and electrodes from environmental influences.

4. Additional Components:

It also includes load capacitors, resistors, inductors, etc., forming a complete oscillation circuit with the quartz crystal.

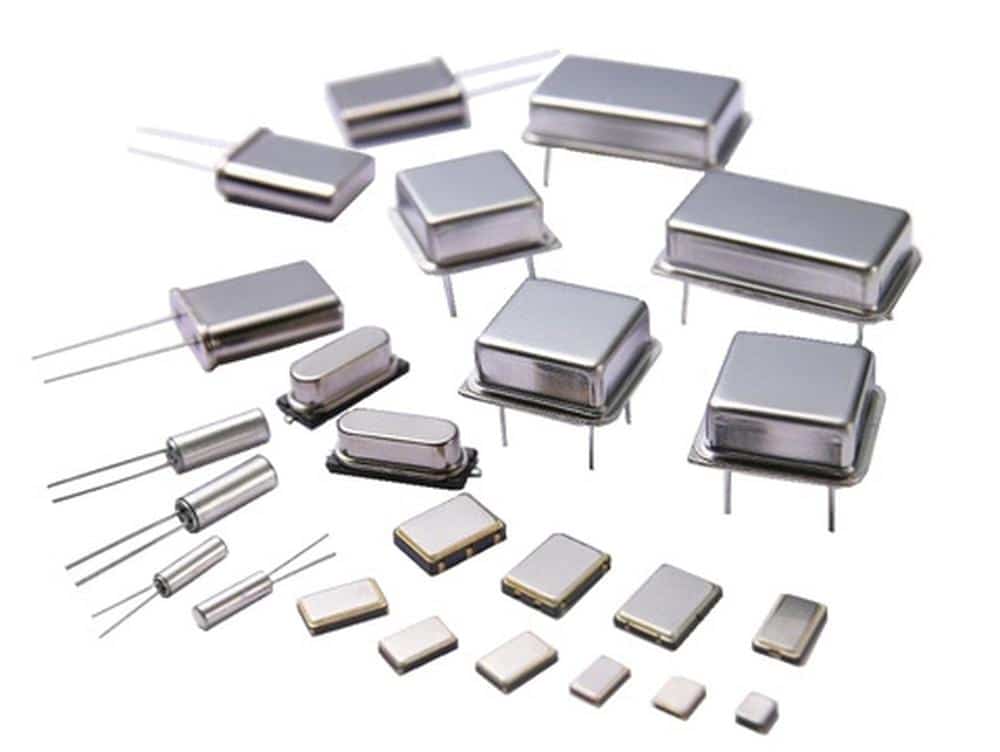

A quartz crystal resonator is made by cutting a quartz crystal at a specific angle (referred to as a wafer, which can be square, rectangular, or circular), coating both surfaces with silver electrodes, welding lead wires to each electrode, and encapsulating the assembly in a protective shell. This forms a quartz crystal oscillator (crystal). When combined with an IC-based oscillation circuit, it becomes a crystal oscillator (XO). These products are usually packaged in metal, glass, ceramic, or plastic enclosures.

Classification of Quartz crystal oscillators

Quartz crystal oscillators are categorized into several types based on their design and performance characteristics.

1.Simple Crystal Oscillator (XO):

Simple Crystal Oscillator (XO) features a straightforward structure and low cost, but its frequency stability is significantly affected by temperature variations, making it suitable for applications with low precision requirements.

2.Temperature-Compensated Crystal Oscillator (TCXO):

Temperature Compensated Crystal Oscillator (TCXO) incorporates peripheral compensation circuits to maintain high frequency stability across different temperature ranges, and is consequently widely used in communications, computing, and consumer electronics. For applications demanding extreme frequency precision and stability, such as satellite communications, radar systems, and navigation equipment.

3.Oven-Controlled Crystal Oscillator (OCXO):

Oven Controlled Crystal Oscillator (OCXO) is employed, which utilizes the constant temperature tank to make the quartz crystal work in a constant temperature environment, with very high frequency accuracy and stability, is often used in the field of satellite communication, radar, navigation and other fields where the frequency stability is required.

4.Voltage-Controlled Crystal Oscillator (VCXO):

Voltage controlled (VCXO): The output frequency of the oscillator can be adjusted by changing the control voltage. It can be used in applications such as frequency modulation and phase locked loop circuit.

Features of Quartz crystal oscillators

High Frequency Stability: Stability up to 10⁻¹²/day or better, ensuring reliable clock signals for electronic systems.

High Precision: Generates highly accurate oscillation frequencies for demanding applications like communications, instrumentation, and control systems.

Strong Reliability: Operates stably under harsh environmental conditions.

Low Power Consumption: Ideal for compact and energy-efficient electronic devices.