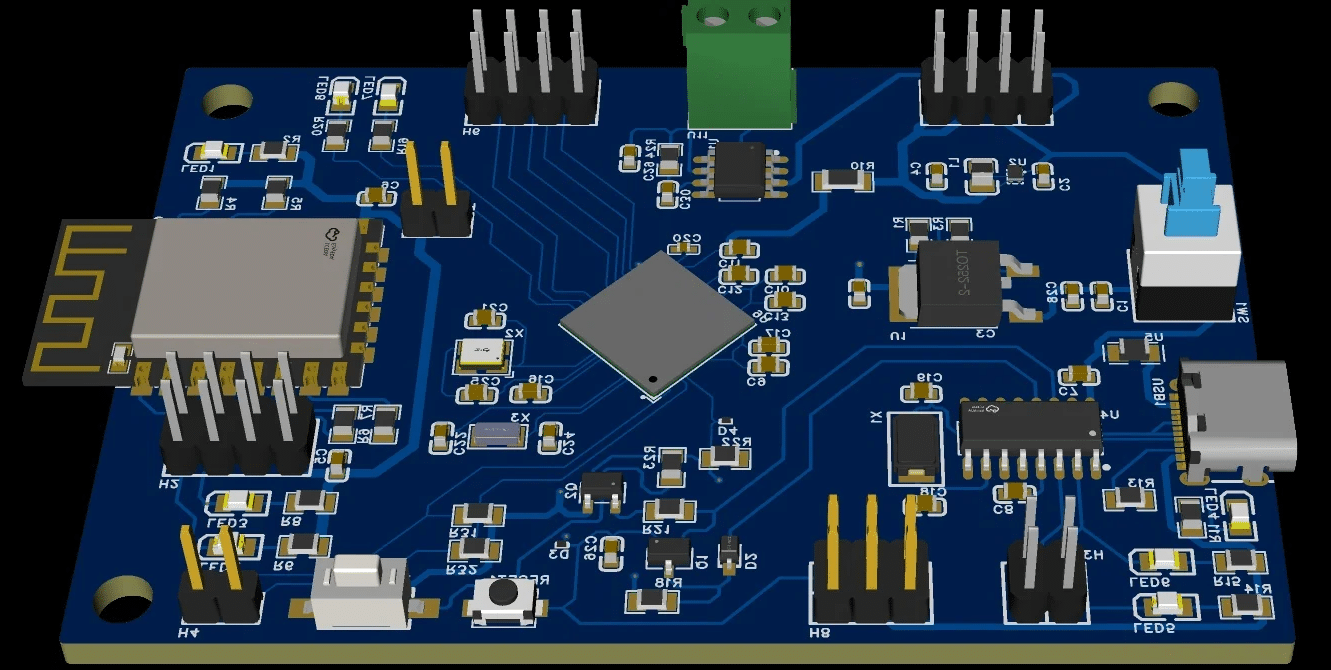

Common Type-C connectors include those used in mobile phones, digital cameras, and scanners. Do you understand the manufacturing process for these products?

Type-C connectors, with their convenient reversible insertion and powerful high-speed transmission capabilities, have become the universal interface for modern electronic devices.

Their manufacturing process is an art that integrates materials science, precision manufacturing, and automation, mainly comprising four stages: stamping, electroplating, injection molding, and assembly. Each stage directly affects the final performance and reliability of the connector.

Stamping: Shaping the Skeleton of the Connection

The manufacturing process begins with precision stamping. Large rolls of thin metal strips (usually copper alloy strips) are fed into a high-speed stamping press and instantly stamped into shape using precision molds, producing the core components of the connector—the terminals and the housing.

The quality of the copper strip is crucial; its ductility, formability, and conductivity directly determine the final mechanical strength and electrical performance of the terminals.

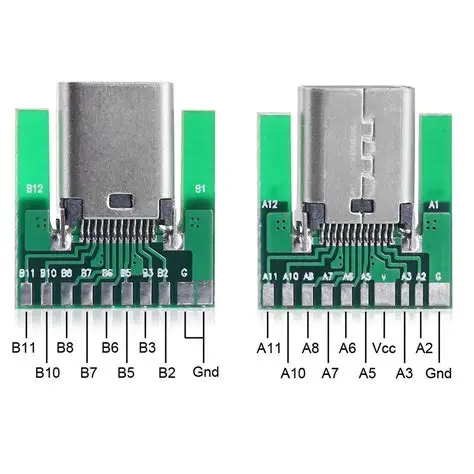

The stamped terminals are the “bridge” for electrical contact in the connector, and their precision must be calculated in micrometers to ensure a stable and tight connection between the male and female connectors.

Electroplating: Imbuing Durability and Conductivity

The stamped terminals then enter the electroplating process. This stage involves plating the terminal contact surfaces with metal coatings such as gold, tin, and nickel, primarily achieving three objectives:

- Improved corrosion resistance: Preventing metal contacts from oxidizing and rusting, ensuring long-term stability.

- Optimized conductivity: Reducing contact resistance, ensuring efficient transmission of high-speed data signals and high-current charging.

- Enhanced wear resistance: The plating (such as gold) can withstand repeated mating and unmating wear, guaranteeing the connector’s lifespan of tens of thousands of cycles. Quality control of the electroplating process is extremely stringent; even the smallest scratch or pinhole can become a potential source of future failures.

Injection Molding: Building an Insulating and Protective Armor

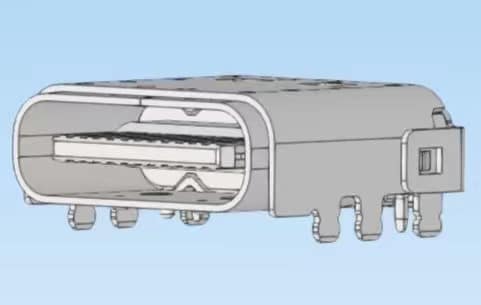

The injection molding process creates a robust insulating shell for the connector. High-temperature molten engineering plastic (such as PBT or LCP) is injected into a precision metal mold and rapidly cooled to form the connector’s core (insulating body).

The core not only provides insulation, preventing short circuits between terminals, but also constitutes the physical framework of the interface, determining the feel of mating and unmating and the overall mechanical strength.

For waterproof Type-C connectors, special sealants (such as epoxy resin) or sealing structures are used during the injection molding process to meet high-level waterproof requirements such as IPX8.

Assembly and Testing: The Final Gathering of Precision Components

The final step is automated assembly. Previously manufactured components such as terminals, housings, and cores are precisely integrated together via a high-speed automated assembly line.

Assembly methods include individual mating and combined mating; regardless of the method, the positioning of each pin must be absolutely precise. After assembly, each connector must undergo rigorous testing, including:

- Insertion and extraction force test: Ensures the feel meets design standards and guarantees connection reliability.

- Electrical performance test: Verifies that data transmission rates and charging power meet specifications.

- High-frequency test (for high-end products): Ensures the integrity of high-speed signal transmission.

Towards a Future of Intelligence and High Reliability

In summary, the production of Type-C connectors is a process with extremely high requirements for precision and quality.

With the advancement of new protocols such as USB 4.0 and Thunderbolt 4, and the growing market demand for waterproof and lightweight designs, the manufacturing process of Type-C connectors is moving towards greater automation, more stringent quality control (such as the introduction of machine vision), and the application of more environmentally friendly materials.

It is this pursuit of excellence at every step that has created the seemingly simple yet incredibly sophisticated multi-functional interface we hold in our hands.