In today’s highly integrated electronic devices, connectors, as crucial bridges for signal transmission and power supply, directly determine the stability and security of the entire electronic system.

Connector insertion and extraction force testing, as a core method for evaluating connector mechanical performance, not only affects user experience (such as the feel of plugging and unplugging a mobile phone charging port) but also determines the signal integrity of the device under complex environments such as vibration and temperature changes.

This article will comprehensively analyze the standard procedures, equipment selection, and innovative industry practices of connector insertion and extraction force testing, providing detailed professional guidance for relevant practitioners.

I. In-depth Analysis of Testing Principles and Core Value

Insertion and extraction force testing scientifically evaluates the mechanical durability and contact reliability of connectors by accurately quantifying insertion and extraction forces. Physically, this test is based on the principle of friction caused by the normal pressure between contact components.

When the male and female ends of the connector are mated, the normal pressure between the terminals generates corresponding friction, the magnitude of which directly determines the value of the insertion and extraction force.

Controlling this parameter is crucial: excessive insertion force leads to operational difficulties and a reduced user experience; while insufficient withdrawal force can easily cause connectors to loosen under vibration, resulting in circuit interruption.

According to the EIA-364-13C standard, substandard connector insertion and withdrawal forces pose a serious risk of failure. Excessive insertion force may cause plastic deformation of the terminals, leading to increased contact resistance and signal attenuation; insufficient withdrawal force may cause contact separation, resulting in circuit breakage or arcing, which is particularly dangerous in high-voltage applications.

Industry data clearly demonstrates the importance of this test: In 2024, the Chinese electronic connector market reached 212.373 billion yuan, with failures due to substandard insertion and withdrawal forces accounting for as much as 12% (data source: Zhiyan Consulting). This figure highlights the critical role of insertion and withdrawal force testing in quality control.

II. International Standards System and Key Parameters Explained

(I) Overview of Mainstream Testing Standards

Currently, the global connector industry has established a complete standards system covering the needs of different application scenarios:

International standard IEC 60512-13-1 specifies the testing requirements for connectors in general electronic devices, emphasizing that the insertion and extraction speed should be controlled at ≤25.4mm/min, and that the force decay curve should be recorded through multiple cyclic tests to evaluate the connector’s durability.

US standard EIA-364-13C sets forth clear requirements for consumer electronics and automotive electronics, such as requiring USB connectors to have an insertion force ≤3.5kgf and an extraction force ≥1.0kgf. This standard particularly emphasizes performance under real-world application scenarios.

Chinese standard GB/T 5095.8-2021 has strict regulations on the testing environment, requiring the ambient temperature to be controlled at 23±5℃ and the humidity to be maintained within the range of 45%~75%, primarily applicable to industrial and military equipment.

The military standard MIL-STD-202G, designed for extreme environments such as aerospace, requires that the pull-out force attenuation rate of connectors under vibration not exceed 15%, ensuring reliability under harsh conditions.

It is worth noting that the parameters differ significantly between different types of connectors. For example, the D-SUB 37P terminal requires a pull-out force ≥3.0 kgf, while the Housing 02P only requires ≥0.5 kgf. This differentiated requirement reflects the precise consideration of application scenarios in the standard’s formulation.

(II) Detailed Explanation of Key Test Parameters

Speed control is crucial for test accuracy. Conventional test speeds are generally 25.4 mm/min (e.g., USB connectors), while precision connectors (e.g., miniature BTB interfaces) require speeds reduced to 12.7 mm/min to obtain more accurate test data.

Cycle count requirements vary depending on the application: consumer electronics typically require 500-5,000 cycles (e.g., mobile phone charging ports), while automotive electronics require ≥10,000 cycles (refer to QC/T 1067 standard), reflecting the higher reliability requirements of automotive electronics.

Environmental variable testing includes verification under special conditions such as temperature (-40℃~125℃), humidity (85% RH), and salt spray environments to ensure stable performance of the connector under various extreme conditions.

III. In-depth Analysis of the Entire Testing Process

(I) Professional Guide to Equipment Selection

Choosing the right testing equipment is fundamental to ensuring testing accuracy:

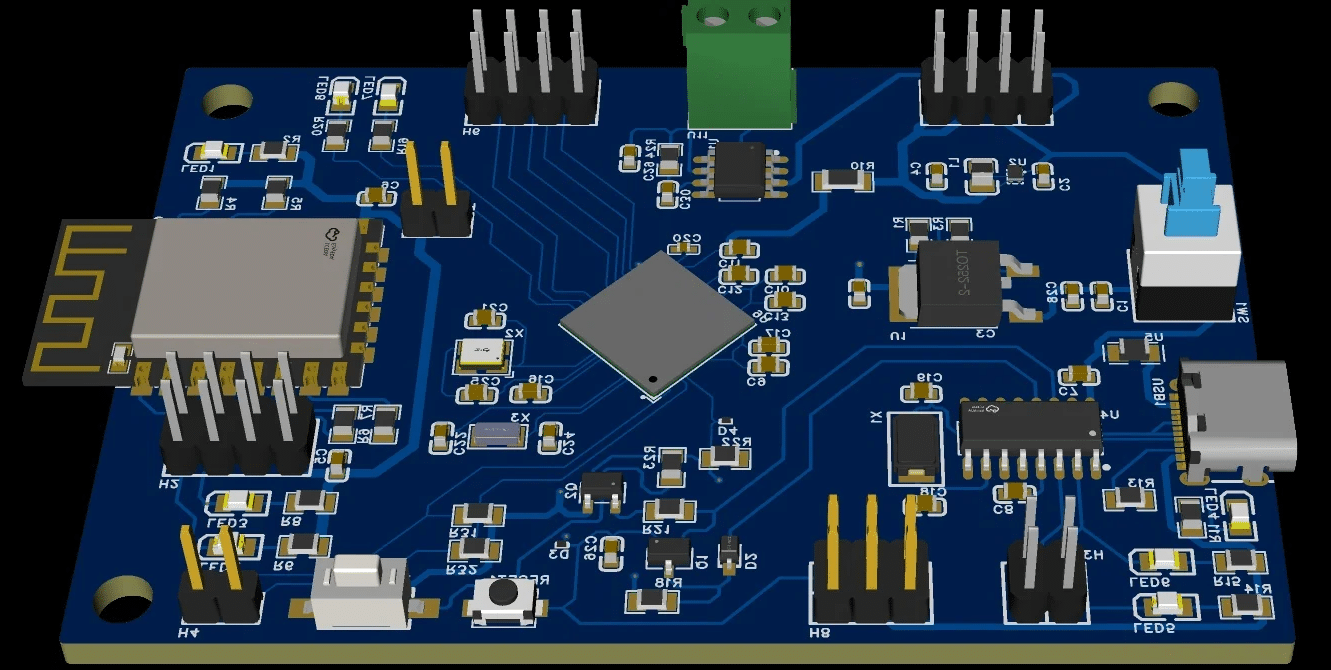

Servo electric testing machines (such as the RS-8115A-5 model) offer high precision of ±0.1mm, support 5 independent testing stations, and are equipped with automatic centering functions to effectively prevent uneven wear and improve testing efficiency.

Universal testing machines (such as the KZ-SSBC-500 model) have a load resolution of up to 0.01g and can be equipped with high-temperature fixtures, making them suitable for various testing scenarios.

High-temperature specialized equipment (such as the patented equipment CN102680152A) employs electromagnetic induction heating, achieving a temperature control accuracy of ±2℃. Combined with heat-insulating ceramic clamps, it enables precise testing in high-temperature environments.

(II) Detailed Explanation of Standardized Operating Procedures

Based on the EIA-364-13C standard, insertion and extraction force testing must follow a strict procedure:

Sample Preparation Stage: A complete set of male and female connectors must be matched, including all accessories (instrument core, shielding shell, screws, etc.). Before testing, the terminals should be cleaned by wiping with alcohol and allowing to stand for 30 minutes to avoid the influence of oxide layers on the test results.

Test Execution Stage: The sample should be correctly installed on the test fixture, ensuring accurate alignment. Set an appropriate test speed and number of cycles, start the test, and monitor data changes in real time.

Data Analysis Stage: A detailed analysis of the insertion and extraction force curves is required to identify abnormal fluctuations. The acceptance criteria are: insertion force ≤ nominal value, and pull-out force ≥ nominal value (e.g., USB connector insertion force ≤ 34.3N / pull-out force ≥ 9.8N).

When the pull-out force decreases by more than 10% for three consecutive tests, the system should issue a failure warning, indicating potential fatigue risk in the contacts.

IV. Advanced Applications of Special Environment Testing Solutions

(I) High-Temperature Insertion and Pull-Out Force Testing Technology

High-temperature testing is conducted using an electromagnetic induction heating device (e.g., patented technology CN102680152A): the connector is heated to a set temperature (maximum 300℃) using a metal cylinder, and a ceramic heat-insulating clamp is used to isolate heat conduction and protect the sensor from high temperatures.

This method can monitor the temperature-insertion and pull-out force change curve in real time, accurately analyzing the impact of material thermal expansion on performance. For example, aerospace engine wiring harness connectors require a pull-out force of no less than 80% of the initial value at 125℃ to ensure reliability under extreme temperatures.

(II) Vibration Superposition Test Scheme

Random vibration (5~150Hz) is applied according to EN 61373 standard, and the pull-out force change is dynamically monitored, requiring an instantaneous interruption time of <1μs. In the new energy vehicle field, the contact resistance change of the connector after vibration testing must be ≤5% to ensure the stability of the power system under complex driving environments.

V. Industry Pain Points and Foresight of Innovation Trends

The current precision bottleneck faced by the industry is mainly reflected in the positioning error of traditional mechanical testing machines >0.5mm. The solution is to use high-precision servo electric cylinders (such as the THK brand) to compress the error to within 0.1mm, significantly improving test accuracy.

In terms of efficiency improvement, multi-station parallel testing technology (400% efficiency improvement for 5-station models) combined with an AI vision-assisted positioning system significantly reduces manual calibration time and improves testing efficiency.

Material innovation brings new possibilities for connector performance improvement: A 0.2μm gold plating on phosphor bronze terminals can extend mating life to 20,000 cycles; LCP plastic housings have a temperature resistance of up to 260℃, effectively reducing deformation issues in high-temperature environments.

Safety Warning: According to GB/T 16915-2023 standard, when the test voltage >30V, an insulating protective cover must be provided to effectively prevent arcing injuries and ensure the safety of testing personnel.

Conclusion

Mating force testing has evolved from a single mechanical index assessment to a systematic evaluation system covering multiple dimensions such as mechanical performance, environmental adaptability, and material properties.

With the rapid development of 5G communication and the new energy vehicle industry, high-frequency and high-speed connectors (such as 112Gbps PAM4 interfaces) pose new challenges to testing technology: nanoscale plating wear monitoring and impedance matching dynamic analysis will become key areas for technological breakthroughs.

Enterprises need to simultaneously upgrade their comprehensive testing platforms (temperature-vibration-mating/extraction linkage) and establish a complete testing and verification system to meet the growing market demand for high-reliability connectors in the future.