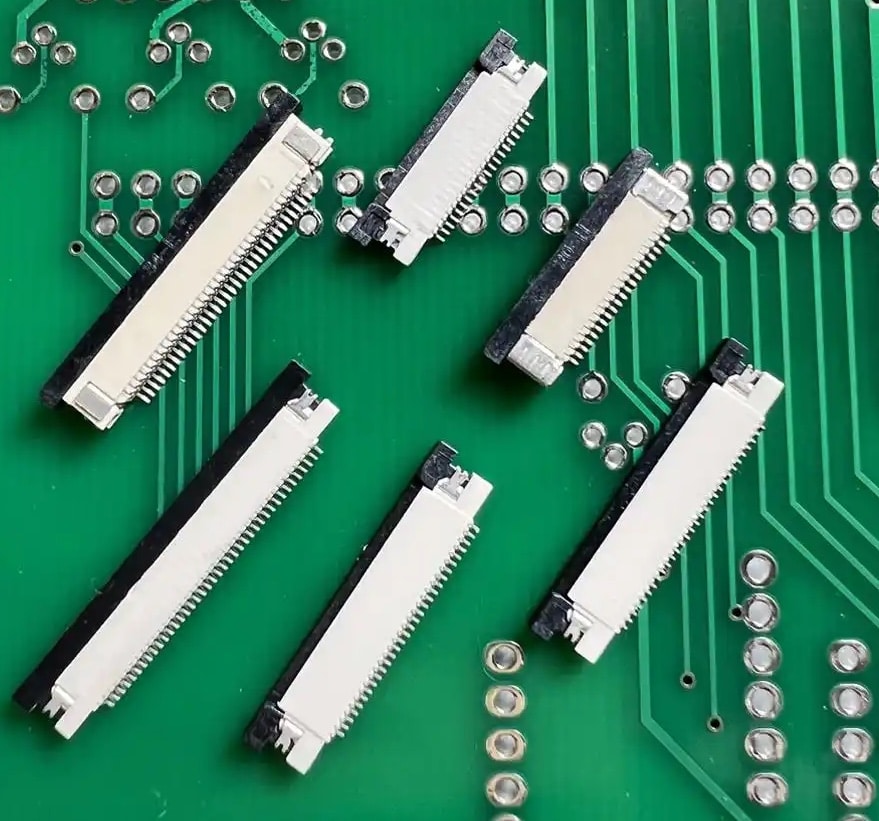

Des: 1mm Pitch FPC Connector top contact drawing ZIF horizontal smt right angle H=2.5

Part No: FPC-1025DU-nP

Specification:

Pitch: 1.0mm

Rate: 0.5A, 50V DC/AC

Pusher type: Drawer, Zif

Packaging: Pcs/Reel

Des: 1mm Pitch FPC Connector top contact drawing ZIF horizontal smt right angle H=2.5

Part No: FPC-1025DU-nP

Specification:

Pitch: 1.0mm

Rate: 0.5A, 50V DC/AC

Pusher type: Drawer, Zif

Packaging: Pcs/Reel

Ensuring the reliability of automotive FPC connectors in high-temperature and high-humidity automotive environments requires systematic consideration. The table below summarizes the core requirements for automotive FPC connectors in terms of material selection and coating processes, allowing you to quickly grasp the key points. Component/Process | Core Requirements | Recommended Selection/Solution Core Requirements Recommended Selection/Solution Connector Housing High heat resistance, high

In the automotive electronics field, 0.3mm pitch FPC connector is favored for their high density and miniaturization advantages, but their reliability in vibrating environments faces serious challenges. The following table provides a quick overview of the core failure modes and corresponding improvement strategies. Failure Mode Classification Typical Manifestation Core Improvement Directions Soldering and Process Failure Poor soldering or fracture between

In the design of compact electronic devices, the selection of what seems to be a tiny FPC/FFC connector can determine the success or failure of a product. This article provides the ultimate guide, delving into the three core elements: Pitch, Actuator Type, and Contact Structure, to help you avoid design pitfalls, optimize your supply chain, and ensure product reliability and

Are you looking for a reliable electronic connector manufacturer to support your business with high-quality products at competitive pricing?