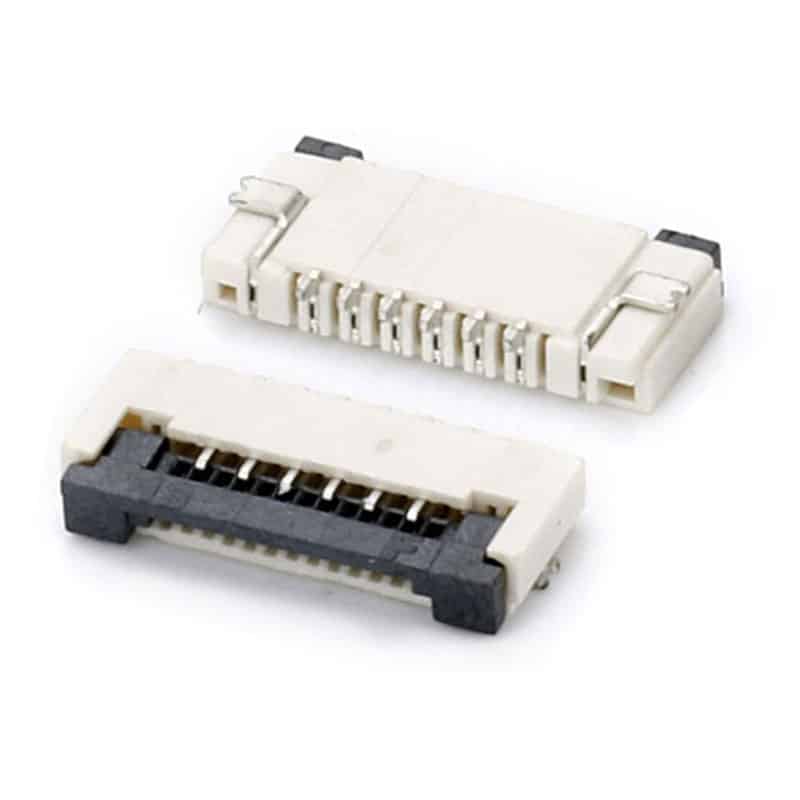

Des: 0.5 mm connector ffc fpc zif H=1.0 back pressure battery fpc connector dual-contact SMT right angle

Part No: FPC-0510BD-nP

Specification:

Pitch: 0.5mm

Rate: 0.5A, 50V DC/AC

Pusher type: Drawer, Zif

Packaging: Pcs/Reel

Des: 0.5 mm connector ffc fpc zif H=1.0 back pressure battery fpc connector dual-contact SMT right angle

Part No: FPC-0510BD-nP

Specification:

Pitch: 0.5mm

Rate: 0.5A, 50V DC/AC

Pusher type: Drawer, Zif

Packaging: Pcs/Reel

The reliability of 0.3mm pitch FPC connectors in vibration environments is a complex system engineering issue, depending on the connector’s design, manufacturing process, and application within the overall system. The table below summarizes the core challenges and key reliability design considerations in vibration testing. Challenges in Vibration Environments Key Reliability Design Measures Contact Failure Risk: Micrometer-level vibrations can cause unstable

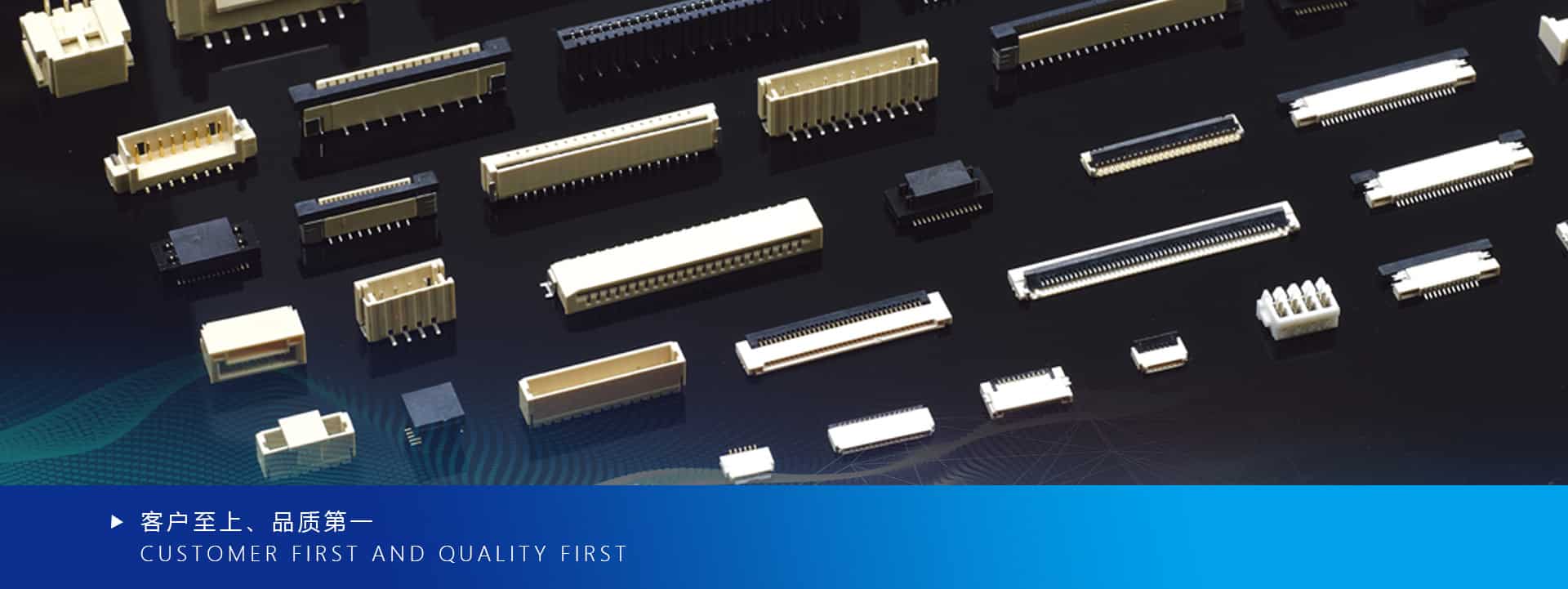

In the electronics manufacturing industry, connectors are indispensable key components responsible for linking circuits and ensuring stable transmission of current or signals. FFC connectors (Flexible Flat Cable Connectors) and FPC connectors (Flexible Printed Circuit Connectors) are two common types of connectors, each with unique characteristics and application fields. Brief Introduction of FFC Connector and FPC Connector FFC connectors are commonly

FPC connectors are a type of electrical connector used to establish a reliable and flexible connection between a flexible printed circuit board and other electronic components or devices. Many pitches are available, such as 0.3 mm, 0.5 mm, 1.00 mm, 1.25 mm, 2.54 mm, but the most common pitches are 0.500 mm, 1.00 mm, and 1.25 mm. A single FFC

Are you looking for a reliable electronic connector manufacturer to support your business with high-quality products at competitive pricing?