Various technologies can be used to regulate the amount of current in a circuit, and slide switches are among the most widely used solutions.

Slide switches provide a compact and reliable way to control circuits, connecting or disconnecting them with a simple linear sliding motion. This brief technical review will examine how slide switches work, explore their main configurations, and outline the electrical and mechanical considerations for optimal selection.

Basics of Slide Switches

A slide switch is an electromechanical component that controls a circuit by moving a linear sliding mechanism. Slide switches open or break a circuit by moving a conductive element, switching between an open (non-conductive) and closed (conductive) state.

As a contact-held switch, a slide switch maintains one position until an intentional actuation force is applied to switch it to the other state, making it a reliable, robust solution for various low-power and space-constrained applications.

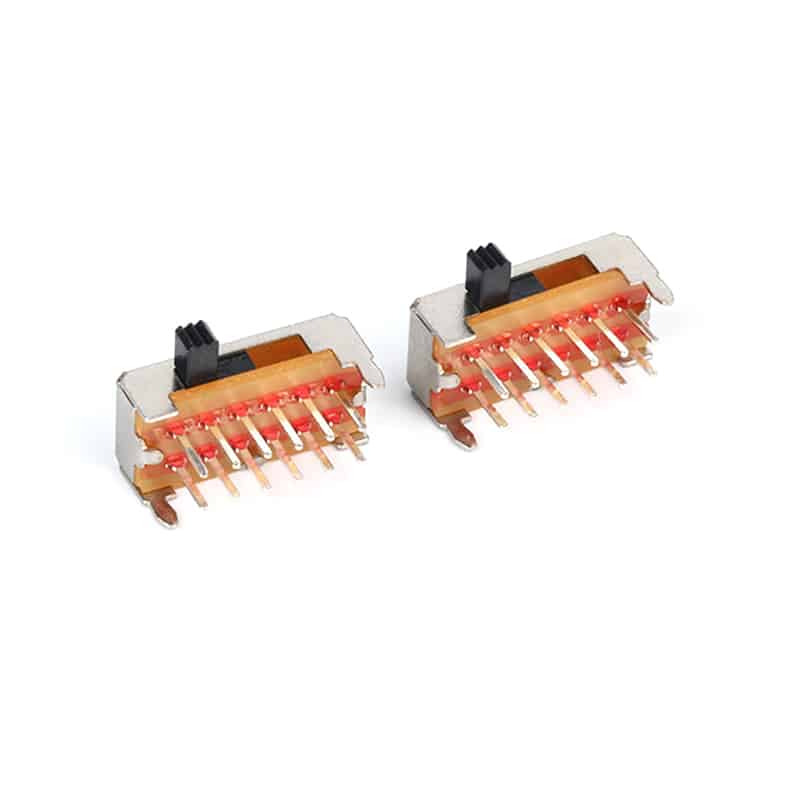

Figure 1: A basic slide switch

Slide switches are typically configured in a single-pole, double-throw (SPDT) configuration, with the ability to reroute current between two different circuits, often referred to as on-on operation. This design allows for seamless switching between power and circuit paths by moving an actuator.

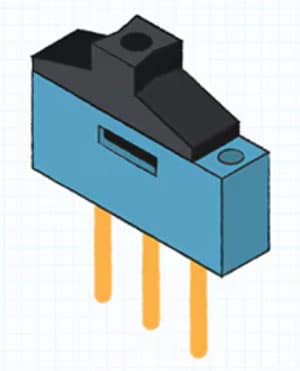

Figure 2: Example of a SPDT switch schematic.

Another widely used configuration is the single-pole, single-throw (SPST) slide switch, which directly controls a switch by making or breaking a circuit.

In applications that require more complex switching functions, a double-pole, double-throw configuration can be used to simultaneously control two independent circuits to achieve a three-position switch (on-off-on, with the center position being off).

For special use cases, slide switches can have multiple throws to achieve multiple two-position switch operations.

However, this can also present practical challenges, such as making it more difficult to accurately position the actuator to the desired setting. We offer slide switches in a variety of circuit types, including SPDT, SP3T, SP4T, DPDT, DP3T, and DP4T.

Important Specifications for Slide Switches

The electrical specifications in the slide switch datasheet define key performance parameters, including voltage rating and current rating, which indicate the maximum electrical load that the switch can reliably handle.

Additionally, key characteristics such as withstand voltage (the maximum voltage the switch can withstand without causing it to fail) and insulation resistance (the resistance between isolated conductive parts) are listed to ensure proper circuit isolation.

In addition to the electrical ratings, mechanical specifications such as actuation travel distance (the displacement required to toggle the switch) and operating force (the force required to actuate the operation) are outlined.

Understanding these values is critical to selecting a switch that meets the electrical and mechanical design requirements.

Slide switches are typically available in surface mount, through-hole, or panel mount configurations. The appropriate mounting method depends on the manufacturing process, available space, and mechanical stresses within the application, specifically switch retention on the PCB or chassis.

Here are other specifications to consider:

· Termination style: Flexibility to accommodate different mounting options, including gull wings, PC pins, wire leads, screw terminals, etc.

· Voltage rating: Defines the maximum voltage allowed across the switch without causing failure. Slide switches are available with voltage ratings ranging from 5 V to 125 V.

· Current rating: The maximum specified current the switch can carry without performance degradation. Slide switches are available with current ratings ranging from 1 mA to 25 A.

· Actuator height: Raised actuators are easier to operate, while flat actuators allow for flush, low-profile designs in equipment housings.

· Pitch: The center-to-center distance between switch terminals, which is critical for PCB layout and compatibility. Common pitches are typically 2 mm to 6.9 mm.

· IP rating: Indicates the degree of protection against the ingress of dust and moisture, a parameter that is important for harsh environments or outdoor applications.

Figure 3: Slide switches with raised and flat actuators.

Slide switches are also categorized by their physical size, with the most common types being subminiature, miniature, and standard. Size selection is critical for applications where space constraints, current capacity, and mechanical integration must be carefully considered.

Because slide switches act as contact-maintained switches, the circuit will maintain its last switched state until the user manually operates the switch again. This is in contrast to pushbutton switches, which can operate in momentary or maintained configurations, depending on the application requirements.

Final Considerations and Applications

Slide switches are commonly found in homes, offices, and industrial environments, and are used in a variety of electronic and electromechanical systems.

Common use cases include computer peripherals, home appliances, consumer electronics, smart home automation, test and measurement equipment, communications hardware, and various industrial control systems.

When integrating a slide switch into a system design, engineers must evaluate application-specific factors to ensure optimal performance and longevity. Other considerations include:

· How many operations can the switch withstand?

The expected number of switching cycles directly affects the life of the switch, and may require a durable switch with minimal contact wear.

· Will the switch be subject to mechanical stress or extreme temperatures?

Harsh mechanical conditions, vibrations, or temperature fluctuations can affect the structural integrity and electrical reliability of the switch.

· Is there a risk of liquid or dust ingress?

If exposure to the environment is a concern, selecting a switch with the appropriate IP rating ensures protection against moisture and particulate ingress.

· What are the electrical requirements?

The switch must be rated to handle the operating voltage and current of the circuit to prevent poor contact, overheating, or electrical failure.

Conclusion

The slide switch is a widely used basic mechanical switch that provides simple, reliable functionality and is primarily used in applications that require a clean, stable transition between two states.

Its intuitive sliding mechanism offers a key advantage: users can confirm the switch’s operating state at a glance, ensuring precise and continuous control of circuit connectivity.

By understanding common configurations, basic electrical and mechanical specifications, and key design factors, engineers can confidently select the best slide switch for their application.

Whether the priority is compact size, durability, or specific electrical ratings, the correct switch selection ensures optimal system performance.