The devil is in the details; though small, cable assemblies are the invisible pillars of modern technology.

In today’s highly interconnected world, cable assemblies, as the “blood vessels” and “nerves” of electronic devices, silently bear the heavy responsibility of power transmission and signal transmission. From household appliances to industrial equipment, from smartphones to spacecraft, behind these seemingly simple cable combinations lies precise engineering design and complex manufacturing processes.

The history of cable assembly development is a microcosm of the progress of electronic technology. This article will delve into the manufacturing process, classification, key technologies, and application areas of cable assemblies, providing readers with a comprehensive analysis of this fundamental yet crucial electronic component.

01 Cable Assembly Manufacturing Process

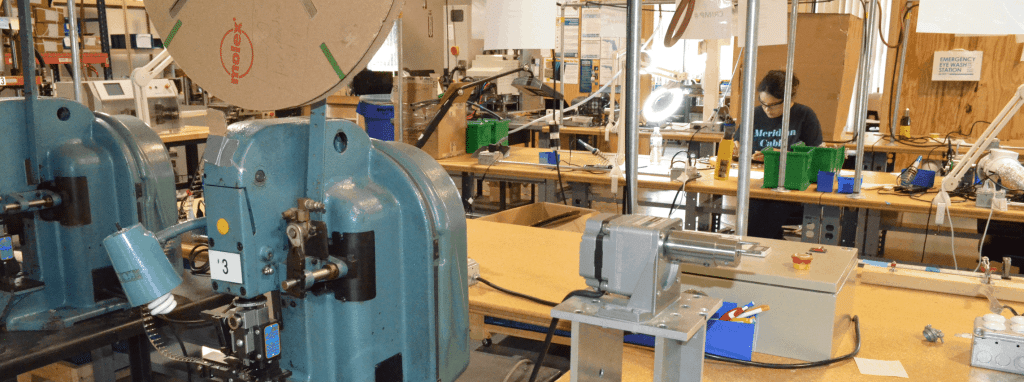

The manufacturing of cable assemblies is a precise and complex process requiring strict process control and quality assurance. According to H3C technical documents, rigorous inspections must be performed before cable assembly, including checking for obvious protrusions, dents, defects, or scratches on the cable surface, and ensuring the integrity of the shielding layer.

The manufacturing process begins with conductor preparation. Copper and aluminum rods commonly used in wire and cable manufacturing are drawn at room temperature through one or more drawing dies using a wire drawing machine. This process reduces their cross-section, increases their length, and improves their strength. Wire drawing is the first step in wire and cable manufacturing, and the key process parameter is die matching technology.

Next is the conductor stranding process. To improve the flexibility of wires and cables and facilitate laying and installation, the conductive core is usually made of multiple single wires stranded together. Based on the stranding pattern, it can be divided into regular stranding and irregular stranding. Irregular stranding is further divided into bundle stranding, concentric stranding, and special stranding.

Insulation extrusion is a crucial step in cable manufacturing. Plastic wires and cables mainly use extruded solid insulation layers. The deviation in the extruded insulation thickness is an important indicator of the extrusion process level. The surface of the extruded insulation layer must be smooth, and there must be no quality problems such as surface roughness, scorching, or impurities.

For multi-core cables, in order to ensure shape and reduce the cable’s overall size, they usually need to be stranded into a circle. This process is called “cabbaging.” Most cables undergo two additional processes during cabling: filling and binding, to ensure the cable’s roundness and stability after cabling.

02 Injection Molding Cable Assemblies

Injection molding (also known as overmolding) cable assemblies offers significant advantages over mechanically constructed products. While complex, specialized manufacturers are willing to invest the extra effort because the final product is not only more attractive but also provides a seal and tamper-proof finish.

The injection molding process involves fitting an unshielded cable assembly into a mold tool designed to precise specifications, then filling the cavity with a suitable molding material to effectively surround the assembly in the desired shape, forming a sealed and well-protected product.

The mold can be designed as a single-cavity or multi-cavity configuration. In a multi-cavity mold, each cavity must be identical to allow for the production of multiple molded parts in a single mold cycle. The choice of mold material depends on production volume: steel molds are suitable for high-volume production, while aluminum molds are better suited for small-batch or prototyping.

Key advantages of injection-molded cable assemblies include:

- Enhanced protection: Highly controlled molding materials and configurations allow for the formation of a bonding layer around the cable and connector, creating a waterproof seal that meets protection standards such as IP-67, 68, and 69K.

- Shock and vibration resistance: The overmolding process helps fill voids around internal components, preventing movement of the overmolded components within the assembly.

- Physical protection: Overmolding helps create an ultra-robust barrier around electronic components, protecting against physical damage from harsh weather, repeated friction, and high temperatures.

03 Flexible Coaxial Cable Assemblies

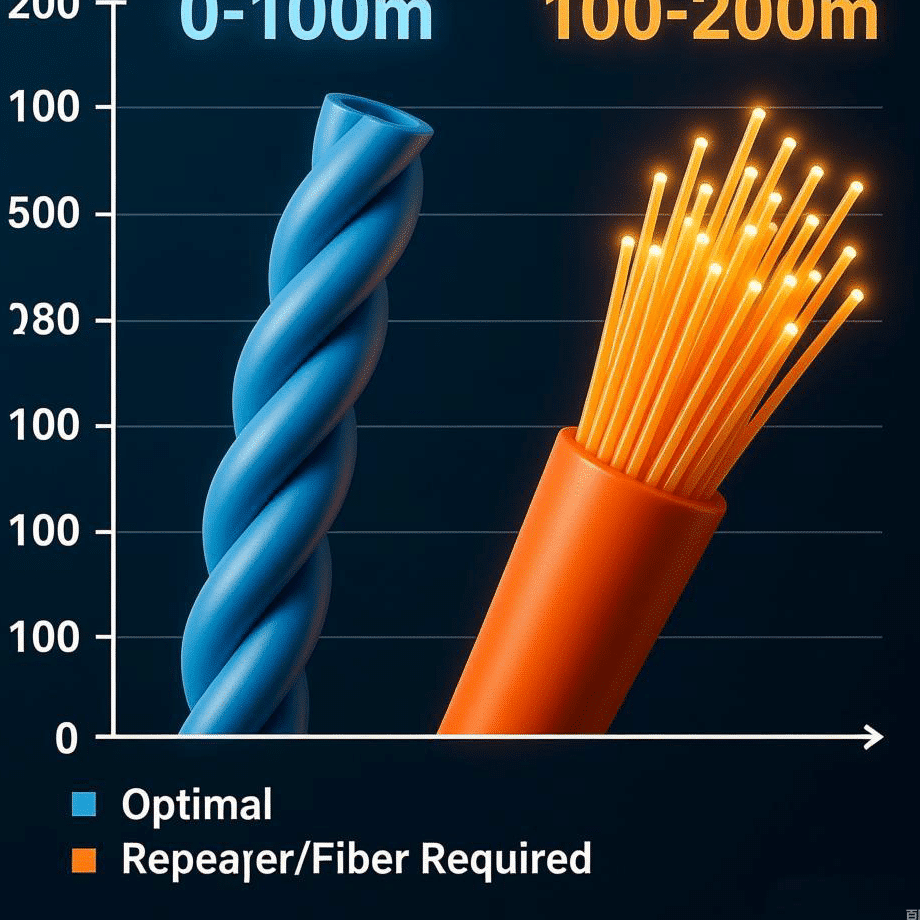

With the increasing demand for high-speed data transmission in electronic devices, flexible coaxial cable assemblies are increasingly replacing FPC/FFC (Flexible Printed Circuit/Flat Flexible Cable). Micro-coaxial cables have a central conductor size ranging from AWG 30-46, a smaller diameter than standard coaxial cables, occupying less space and offering greater flexibility due to their smaller diameter.

Microcoaxial cable assemblies range in diameter from 0.22 to 1.16 mm and, due to their small conductor size, can operate in a frequency range from DC to 6 GHz. These cables offer high signal transmission speeds and flexibility, making them increasingly common in applications requiring high-speed signal characteristics and mechanical stability.

Key advantages of microcoaxial cables include:

- Excellent impedance controllability: Microcoaxial cables ensure signal integrity by controlling impedance. The cable’s center conductor, insulator, and outer conductor can be matched and stabilized at a specific impedance.

- Superior shielding: The outer conductor of the microcoaxial cable protects the signal from electromagnetic interference, while its excellent shielding reduces crosstalk between signals.

The assembly process of flexible microcoaxial cable assemblies involves several precision steps, including preparing cable subassemblies according to type, fitting this part to the plug housing assembly, and fixing the exposed parts to the plug signal terminals by soldering.

04 Types and Applications of Cable Assemblies

Depending on the application environment and requirements, cable assemblies can be classified into various types. Open-type cable harnesses connect cables and harness assemblies to connectors and terminals, and are bundled together using plastic cable ties or waxed thread. Closed-type cable harnesses use covering materials to bind the wires, such as pulled braided tubing, braided Nomex, or nylon.

Waterproof cable harnesses are another important type, with the connection between the connector legs and the back shell molded from materials such as polyurethane or rubber compounds. These harnesses are crucial in humid environments such as automotive, marine, and outdoor equipment.

The electrical parameters of cable assemblies are critical to their applications. Typical cable assemblies have a rated voltage of 30V AC/DC, a withstand voltage of 200V AC/min, a temperature range of -25 to 85°C, and an insulation resistance ≥100MΩ. These parameters determine the applicable scenarios and conditions for the cable assembly.

In construction machinery, cable assemblies play a vital role. Cable harnesses not only ensure the transmission of electrical signals but also guarantee the reliability of connected circuits, provide the specified current values for electronic and electrical components, prevent electromagnetic interference to surrounding circuits, and avoid electrical short circuits.

05 Quality Control of Cable Assemblies

Quality control of cable assemblies is a crucial step in ensuring their reliability. Taking Ethernet cables as an example, rigorous inspection is mandatory after assembly. According to Huawei’s technical guidelines, the inspection includes: the height and dimensions of the metal contact pieces must be standardized; the contact pieces must be parallel to each other with an offset of less than ±5°; and the contact surface must be clean and free of foreign matter.

Cable testing is another important aspect of quality control. For Ethernet cables, a cable tester can be used for verification. After inserting the cable connector into the RJ-45 port of the tester, gently shake the connector to confirm reliable contact between the connector and the RJ-45 port. The order in which the indicator lights on the main and remote ends of the tester display information indicates whether the cable is qualified.

For more sophisticated micro-coaxial cable assemblies, the assembly process requires extremely high precision. The central conductor must be connected to the circuit signals on the board through the connector contacts. Furthermore, the outermost conductor should be electrically connected to the board through a metal component (called the shell) within the connector. This process requires specialized tools and skilled technicians.

The minimum bending radius of the cable is also an important consideration in quality control. According to H3C guidelines, the bending radius of additional power cables, communication cables, or ribbon cables should be at least five times the cable’s outer diameter. If the cable is frequently bent, connected, and disconnected, the bending radius should be at least seven times the cable’s outer diameter.

06 Development Trends of Cable Assemblies

With the increasing functionality of electronic devices and the widespread application of electronic control technology, the number of electrical components and wires is also increasing. How to more effectively and rationally arrange a large number of wire harnesses within the limited space of engineering vehicles, allowing them to play a greater role, has become a problem facing the engineering vehicle manufacturing industry.

Lightweighting and high performance are the main development directions for cable assemblies. Modern automobiles have introduced CAN bus configurations, using multiplexing systems. Compared with traditional point-to-point configurations, CAN bus significantly reduces the number of wires and connectors, making the wire harnesses lighter.

High signal transmission speed is another important trend. With the continuous improvement of internet speeds and the widespread use of large-memory devices, the demand for high-speed data transmission is growing. Micro-coaxial cable assemblies are an ideal choice to meet this demand.

Environmental protection and safety have also become important considerations in the development of cable assemblies. More and more cable assemblies are using RoHS-compliant environmentally friendly materials and have passed various safety certifications such as VDE, UL, and CSA. These certifications ensure that cable assemblies meet international standards in terms of safety, reliability, and environmental friendliness.

Customization needs are also becoming increasingly prominent. Customizing cable assemblies according to specific customer requirements, including connector type, cable length, color, and appearance, has become an important service for cable assembly manufacturers. Customization allows cable assemblies to better adapt to specific application scenarios and environmental requirements.

In the future, with the rapid development of 5G, IoT, and AI technologies, cable assemblies will evolve towards higher frequencies, higher speeds, and smaller sizes. Lightweighting and high performance will become the main development directions for cable assemblies.

The application of new materials and processes will continuously improve the performance indicators of cable assemblies, meeting the ever-increasing demand for high-speed data transmission. It is foreseeable that cable assemblies, seemingly ordinary electronic components, will continue to play an indispensable role in the digitalization process.

The world of cable assemblies is full of challenges and innovation. As one engineer said, “Details determine success or failure.” In the design and manufacturing of cable assemblies, every detail is related to the reliability of the entire system.