In the automotive electronics field, 0.3mm pitch FPC connector is favored for their high density and miniaturization advantages, but their reliability in vibrating environments faces serious challenges. The following table provides a quick overview of the core failure modes and corresponding improvement strategies.

| Failure Mode Classification | Typical Manifestation | Core Improvement Directions |

| Soldering and Process Failure | Poor soldering or fracture between the FPC pad and the connector or nickel plate due to thermal stress or vibration. | Optimize soldering process, improve FPC structural design, strengthen process control. |

| Connector Body Failure | Vibration leads to increased contact resistance or even momentary disconnection; loose locking mechanism causes FPC cable to detach. | Select high-reliability connectors (e.g., multi-point contact, robust locking mechanism), ensure proper assembly. |

| Design and Application Failure | Misalignment during assembly, insecure cable fixing, leading to connector damage or cable breakage under vibration. | Optimize layout and fixing methods, use automated precision assembly, conduct thorough verification. |

In-depth Analysis of Typical Failure Cases

- Failure of FPC Connector Soldering in Automotive Batteries: A very specific case occurred inside an automotive battery, where the nickel plate on the FPC connector board and the FPC pad experienced poor soldering under the combined effects of vibration and thermal stress.

The root causes included: a 50-60μm step difference (sinking) in the FPC pad, leading to stress concentration; large voids (up to 75%) in the solder joint with flux residue; furthermore, the covering PI film created a completely sealed space for the solder joint, preventing the escape of internal gases during secondary reflow soldering. The resulting immense stress caused the solder joint to separate from the good IMC layer, resulting in poor soldering.

This case clearly demonstrates that even if the connector itself is intact, the soldering process and structural design of its connection with the FPC are crucial. - Connector Contact and Locking Mechanism Failure: In a vibrating environment, small, continuous vibrations can wear down the gold plating, leading to increased contact resistance and unstable signals. In more severe cases, vibration can cause the FPC cable to slightly detach from the 0.3mm pitch connector, resulting in momentary signal interruption.

If the connector’s locking mechanism (such as a flip-lock actuator) is poorly designed or insufficiently locked, vibration can even cause it to completely detach. Some high-end connectors (such as certain Kyocera models) use movable structures to absorb substrate misalignment and vibration, thereby improving connection stability. - Collateral damage caused by improper cable fixing: If the cable connected to the FPC connector is too long and not properly secured in a vibrating environment, the energy from vibration and shock will be directly transmitted to the connection point. This can not only cause the cable itself to break, but also endanger the fragile 0.3mm pitch connector, leading to solder joint cracking or plastic housing damage.

Systematic Improvement Solutions

To improve the reliability of 0.3mm pitch FPC connectors in vibrating environments, a systematic optimization is needed, from materials and design to processes and testing

- Optimizing Welding Process and FPC Design

To address the problem of poor soldering, improvements can be made at the design and process levels:

- Improve FPC design: Minimize height differences in the solder pads to ensure even contact between the nickel plating and the pads, thus distributing stress.

- Improve process control: Bake the FPC before assembly to remove moisture. Optimize the stencil design (e.g., increase thickness, add venting channels) to increase solder paste volume and reduce soldering voids. Strictly clean flux residue.

- Adjust sealing design: Avoid creating a completely sealed space above the solder joints. For example, consider using dispensing sealant after reflow soldering instead of a fully covering PI film.

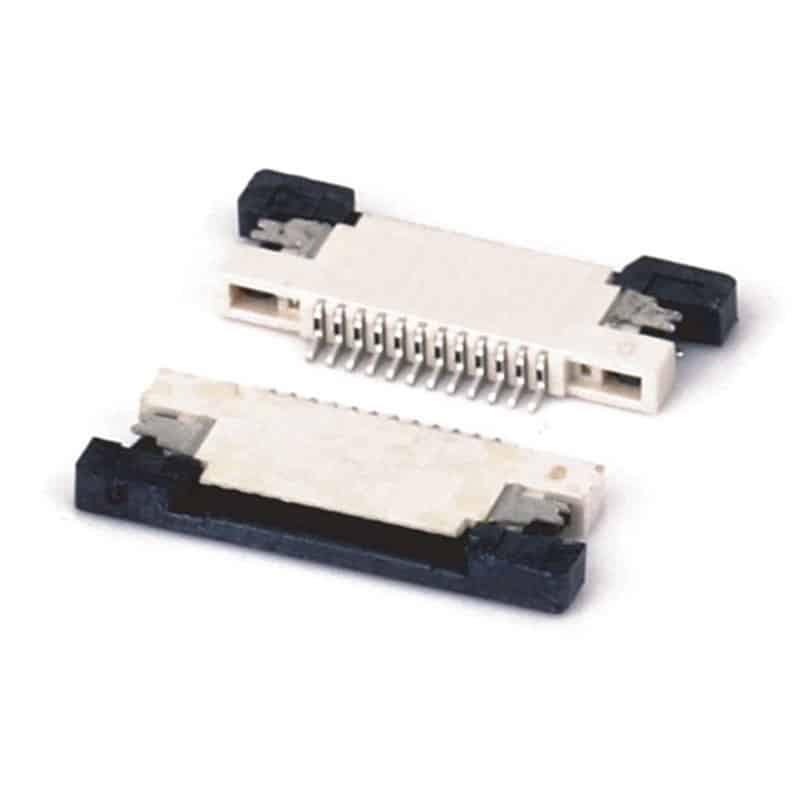

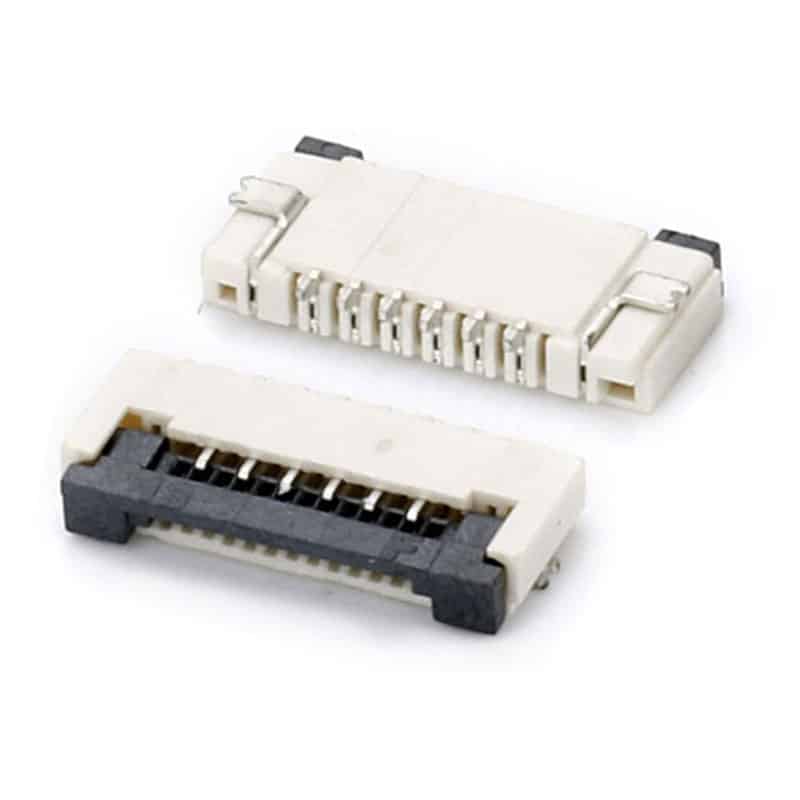

- Selecting High-Reliability Connectors

When selecting connectors, special attention should be paid to their vibration-resistant design:

- Contact point design: Prioritize models with dual-contact or multi-point contact designs. This redundant design ensures that even if one contact point is affected by vibration, other contacts can still maintain a conductive path.

- Locking Mechanism: Select a locking mechanism with a high retention force and a clear locking feel (such as some flip-lock or slide-lock designs) to ensure the FPC is securely locked after insertion.

- Terminal Material: Pay attention to whether the terminals use high-performance phosphor bronze or beryllium copper, as these materials provide more stable and durable contact pressure.

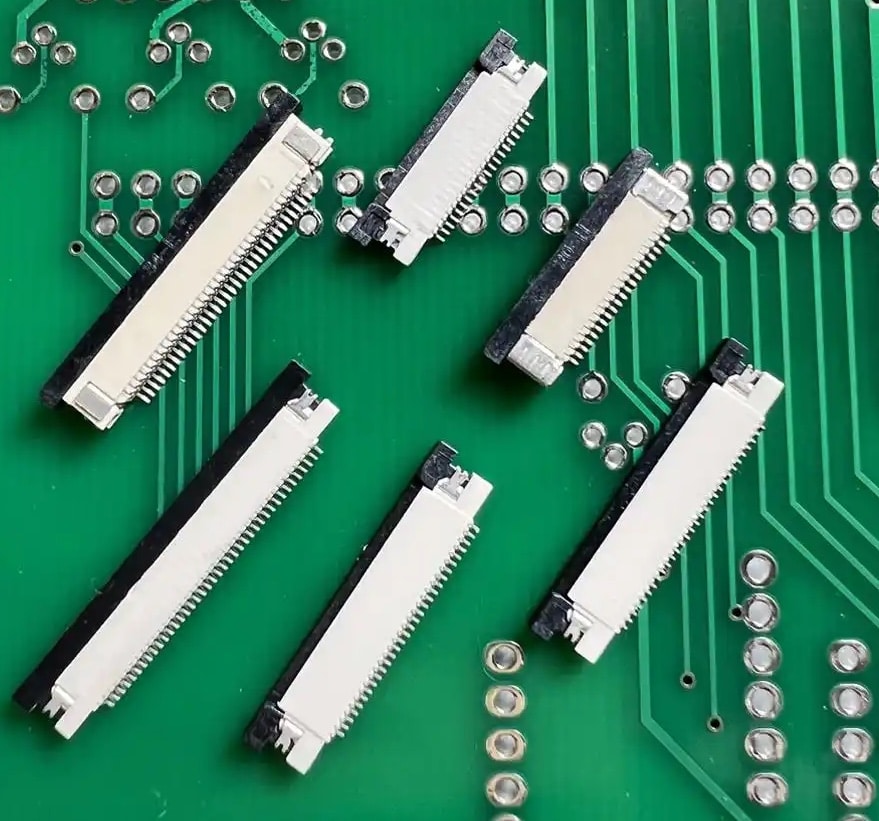

- Strengthen System-Level Assembly and Fixing

In the overall system design, a good working environment must be provided for the connector:

- Precision Assembly: The 0.3mm pitch fpc connector requires extremely high precision for insertion and removal. It is recommended to use high-precision jigs and, as much as possible, use automated equipment to avoid human error.

- Cable Fixing: Strictly follow the specifications and use cable clips or other fixing methods to effectively secure the cables at the back of the connector to prevent vibration energy transmission.

- Auxiliary Reinforcement: If space and process allow, a small amount of special electronic adhesive (such as epoxy resin) can be applied around the connector after mating to enhance vibration and shock resistance.

- Optimized Layout: When designing the PCB layout, try to place the connector near rigid support points such as screw fixing points on the board, avoiding positions that are suspended or easily deformed.

- Implement Strict Vibration Testing and Failure Analysis:

During the product verification phase, sufficient vibration testing must be conducted:

- Test Standards: Follow national standards such as GB/T 2423.10 or relevant industry standards for testing.

- Monitoring Indicators: During testing, not only should continuity be monitored, but also the change in contact resistance should be continuously monitored, requiring the change to be very small (e.g., less than 5mΩ or 10% of the initial value).

- Failure Analysis: After testing, the samples should be subjected to microscopic inspection, X-ray inspection, and even cross-sectional analysis to find microscopic cracks or damage in the solder joints, terminals, or the FPC itself, identifying the root cause of the problem.

Summary

By carefully selecting connectors, optimizing design and processes, strengthening system assembly, and conducting rigorous testing and verification, 0.3mm pitch FPC connector can meet the requirements of high-vibration scenarios such as automotive electronics.

We hope these specific examples and systematic solutions will be helpful to your project! If you encounter more specific situations in your application, please feel free to continue the discussion. More info, please refer to this guide about the FPC connector.